- 3,246

- 2,955

- 113

- Location

- Brooklyn, NY

I'm not trying to speak sacrilege here, and I don't want to precipitate a war of words.

How might I build a manual control box? My 24Volt Landcruiser just uses a glow wire to show glow plugs are ready, and then she just starts right up with the twist of a key.

Civilian 6.2 Diesel engines don't seem to have a PCB. My slantback is now a personal use vehicle. It is awesome right now but in the future I want to personalize it.

So what needs to be done to bypass and create a working manual "box"? (1987 6.2 with TH400)

(I'm aware of things like overheating and blowing out the glow plugs.)

Best,

T

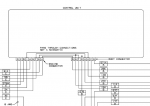

EDIT - post 51 shows schematics as I originally listed them, BUT i decided to post them here on Post #1 to make life easier for the St.So. Family. Happy Independence Day 2022!!!

EDIT - Sept 09, 2023. WARNING! This is a potentially dangerous device that can risk your life and limb. It is not to be taken or undertaken lightly when built or used. Reminder to those who don't read the entire thread... Depressing glow plug button more than 5 continuous seconds or pressing repeatedly may lead to failure and permanent damage. Build at your own risk. I take no responsibility for these plans or anything built utilizing these plans in part or in their entirety. Screwing up the wiring or parts, (or even doing it correctly), can result in catastrophic damage and injury. Even OEM PCB/EESS units have been known to damage vehicles, (including and not limited to those OEM units creating catastrophic damage and fires that risk life and limb and vehicle and surrounding property/structures). This is just posted educational material... It is YOU who takes and assumes all risks, losses and damages, Including but not limited to legal physical financial or anything else. Even OEM PCB/EESS units have been known to damage vehicles, (including and not limited to those OEM units creating catastrophic damage and fires that risk life and limb and vehicle and surrounding property/structures). This is just posted educational material... It is YOU who takes and assumes all risks, losses and damages, including but not limited to physical human damages, legal damages, property damages, life threatening damages, financial damages, and any and all other risk and damages.

How might I build a manual control box? My 24Volt Landcruiser just uses a glow wire to show glow plugs are ready, and then she just starts right up with the twist of a key.

Civilian 6.2 Diesel engines don't seem to have a PCB. My slantback is now a personal use vehicle. It is awesome right now but in the future I want to personalize it.

So what needs to be done to bypass and create a working manual "box"? (1987 6.2 with TH400)

(I'm aware of things like overheating and blowing out the glow plugs.)

Best,

T

EDIT - post 51 shows schematics as I originally listed them, BUT i decided to post them here on Post #1 to make life easier for the St.So. Family. Happy Independence Day 2022!!!

EDIT - Sept 09, 2023. WARNING! This is a potentially dangerous device that can risk your life and limb. It is not to be taken or undertaken lightly when built or used. Reminder to those who don't read the entire thread... Depressing glow plug button more than 5 continuous seconds or pressing repeatedly may lead to failure and permanent damage. Build at your own risk. I take no responsibility for these plans or anything built utilizing these plans in part or in their entirety. Screwing up the wiring or parts, (or even doing it correctly), can result in catastrophic damage and injury. Even OEM PCB/EESS units have been known to damage vehicles, (including and not limited to those OEM units creating catastrophic damage and fires that risk life and limb and vehicle and surrounding property/structures). This is just posted educational material... It is YOU who takes and assumes all risks, losses and damages, Including but not limited to legal physical financial or anything else. Even OEM PCB/EESS units have been known to damage vehicles, (including and not limited to those OEM units creating catastrophic damage and fires that risk life and limb and vehicle and surrounding property/structures). This is just posted educational material... It is YOU who takes and assumes all risks, losses and damages, including but not limited to physical human damages, legal damages, property damages, life threatening damages, financial damages, and any and all other risk and damages.

Last edited: