- 7,032

- 2,690

- 113

- Location

- Montevideo/Uruguay

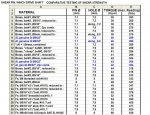

Well, finally.... did some more testing, including all kind of materials combining different hole and pin diameters...... and found at least some that could be considered good alternatives to the original genuine GI spec aluminum shear pins!..................................

Also thinking of including some steel in the next test series, for the sake of completeness...........!Guess I then need to build a heavy duty "pin cracker" with a hardened shaft...!

G.

A VERY BIG THANK YOU to Kenny (Recovry4x4) for sending me these to have for comparison!!!!!!

(For anyone interested there still are some more left for further experiments.)

In general the torque figures were relatively consistent and predictable comparing similar material and sizes. Pin diameter matters much more then hole diameter or shape. Obviously it makes a big difference if a bolt sticks with its full diameter inside the shaft or is threaded partially or full length.

The chart (and pics) below show what was done. Hope it is easy enough to understand.

Enjoy!

G.

Attachments

-

106 KB Views: 329

-

68.9 KB Views: 235

-

75.5 KB Views: 220

Last edited: