Barrman

Well-known member

- 5,460

- 2,188

- 113

- Location

- Giddings, Texas

Some back ground first.

Direct Drive 27MT 24 volt starter.

Rebuilt by a very good rebuilder a year ago next week after it wouldn't turn the engine anymore. Basically all internal parts new. New solenoid with "24V" stamped in the side of it.

I have never let the starter turn more than 5 seconds in the past year. The truck normally starts in less than 1, maybe crank to 2-3 if the engine temp is such that the plugs don't come on.

Basically, a good starter with very little wear.

Dog head relay installed when the starter was put back in last year.

Thursday after we had an Eagle Board of Review for one of my Scouts. I fired up the M1009 to go home. The engine started right up as usual. I heard a humming/whirring noise. Thinking alternator or power steering pump issues, I turned off the key. The engine died and the noise continued. Hmmm, then IT"S THE STARTER! clicked in my mind.

I tried the key again and the relay under the dash clicked each time I tried it. Starter motor continued to spin, but the engine wasn't turning over. I popped the hood, grabbed a flash light and went to pull battery terminals off.

I like to keep mine tight. None of them wanted to budge and my wrenches are in an ammo can in the back of the truck. I didn't want my expensive starter to burn up so I tried the terminal leads again. The front battery negative terminal moved and I eventually got it off. Starter motor stopped turning.

Now that it was stopped, I went running to the last other person left in the lot to ask for a drag home. 30 seconds to a minute later I was back at the truck. I saw lots of smoke and glowing red wires. By the time I got the wrenches out and the other 3 terminals off. It looked like the entire wiring harness was smoked.

I stood there thinking evil thoughts about all things mechanical, pushed the truck back a few feet so I could be towed and got the tow strap out. By that time, the smoke was gone.

I confirmed that no more wires were burning and tried to hook up the front cables so I would have lights and flashers for the tow strap trip home. No sparks, no noises and the lights worked. All the idiot lights came on when I turned the key too far trying to free up the steering wheel.

No problems on the 5 mile tow home. I pulled the battery terminals off, looked for anymore smoke and just went inside for the night.

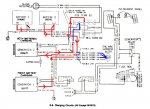

Looking through the wiring diagrams the next day I realized what I had done.

Pulling the BAT 1 negative lead caused the BAT 2 8 gauge negative wire to carry all the load of turning the starter. Its fusable link burned at the engine wiring harness block over next to the glow plug relay.

The starter relay 24V feed wire also burned its fusable link at the firewall buss bar. Another 8 gauge wire.

The ALT 2 8 guage negative also burned at the engine wiring harness block along with another fusable link I never did figure out what circuit it belonged to.

So, the wiring wasn't a total loss.

What happened though? The starter motor had turned the engine and the solenoid had engaged the Bendix to make the engine start. The way it is supposed to work. Then, just the motor was spinning without the Bendix engaged. That to me means starter solenoid malfunction.

I could hear the starter relay under the dash clicking which while it doesn't mean it isn't sticking, doesn't point to it as the problem either.

I carry a spare starter I rebuilt a year ago in the back of the 1009. My mission Saturday was to fix all the wiring, drop the thought to be bad starter, test the system out with no starter installed and then put in my spare.

I was able to find a 10' roll of 12 gauge fusable link wire at our local Car Quest along with crimp on ring terminals just in case I didn't have enough already in my electrical kit. $10 spent.

Attached is a picture of all the burned links I cut out sitting next to each other. Once I had them all cut off, I got out my yellow crimp butt connecters and found they don't fit 8 gauge wire. Another trip to town and I found Car Quest part number SST80. That is a 10-12 gauge crimp butt connector that comes with no insulation. Just the way I like them. $2.00 spent.

Back home and everything got wired back up. The other attached pictures show the replaced fuseable links. They are clean, light blue and have red/pink shrink wrap on them. Yellow cover end terminals too. Pretty much the pictures show you which wires will burn if you just pull the front battery negative terminal during a runaway starter event.

I pulled the starter and made sure the power in wires weren't touching anything. I had Colton get inside once I hooked up the batteries and try the key. No voltage to the purple solenoid wire unless he was turning the key to start. Off and on half a dozen times. All working good. Has to be the starter solenoid.

I put a DVOM on the solenoid and could not find conductivity between the main power in to the solenoid and the power in from the solenoid to the starter motor. Hmm. I thought that was it for sure.

I hooked up some jumper cables, put my foot on the starter and used a screw driver. Worked perfect. Bendix popped right out and the motor spun right up. Again and again and again. Thats not right.

I tested my carry around with me spare and it did nothing. Good thing I didn't need it.

I had another spare and it tested great. I installed it and the truck fired right up. Except, the voltage meter stayed right at the yellow/green line. Now what?

I turned it off, checked everything with the alternators and it looked ok. Batteries 12.4/12.5 engine off and 13.7/13.7 with the engine running. It starts and I can live with a low charge just driving around town. One entire day spent fixing this thing and I still didn't know what failed, why or if my alternators got zapped in the regulator some. At least it runs and I can drive to work Monday.

This morning I checked the batteries and 12.7/12.7 what what I found. Fired it up and the needle went to the middle of the green. 14.4/14.4 on the batteries with the engine running. All good.

I still think it is the solenoid that failed. However, since the starter ran for at least 1 minute if not more. It might have smoked itself some. Back to the rebuilder it will go next week. Along with my thought to be good spare starter.

Sorry for the long post, but I wanted to cover all the facts and relay what was done. The lesson here is that nothing is for sure ok and pulling just one battery cable will cause troubles.

Direct Drive 27MT 24 volt starter.

Rebuilt by a very good rebuilder a year ago next week after it wouldn't turn the engine anymore. Basically all internal parts new. New solenoid with "24V" stamped in the side of it.

I have never let the starter turn more than 5 seconds in the past year. The truck normally starts in less than 1, maybe crank to 2-3 if the engine temp is such that the plugs don't come on.

Basically, a good starter with very little wear.

Dog head relay installed when the starter was put back in last year.

Thursday after we had an Eagle Board of Review for one of my Scouts. I fired up the M1009 to go home. The engine started right up as usual. I heard a humming/whirring noise. Thinking alternator or power steering pump issues, I turned off the key. The engine died and the noise continued. Hmmm, then IT"S THE STARTER! clicked in my mind.

I tried the key again and the relay under the dash clicked each time I tried it. Starter motor continued to spin, but the engine wasn't turning over. I popped the hood, grabbed a flash light and went to pull battery terminals off.

I like to keep mine tight. None of them wanted to budge and my wrenches are in an ammo can in the back of the truck. I didn't want my expensive starter to burn up so I tried the terminal leads again. The front battery negative terminal moved and I eventually got it off. Starter motor stopped turning.

Now that it was stopped, I went running to the last other person left in the lot to ask for a drag home. 30 seconds to a minute later I was back at the truck. I saw lots of smoke and glowing red wires. By the time I got the wrenches out and the other 3 terminals off. It looked like the entire wiring harness was smoked.

I stood there thinking evil thoughts about all things mechanical, pushed the truck back a few feet so I could be towed and got the tow strap out. By that time, the smoke was gone.

I confirmed that no more wires were burning and tried to hook up the front cables so I would have lights and flashers for the tow strap trip home. No sparks, no noises and the lights worked. All the idiot lights came on when I turned the key too far trying to free up the steering wheel.

No problems on the 5 mile tow home. I pulled the battery terminals off, looked for anymore smoke and just went inside for the night.

Looking through the wiring diagrams the next day I realized what I had done.

Pulling the BAT 1 negative lead caused the BAT 2 8 gauge negative wire to carry all the load of turning the starter. Its fusable link burned at the engine wiring harness block over next to the glow plug relay.

The starter relay 24V feed wire also burned its fusable link at the firewall buss bar. Another 8 gauge wire.

The ALT 2 8 guage negative also burned at the engine wiring harness block along with another fusable link I never did figure out what circuit it belonged to.

So, the wiring wasn't a total loss.

What happened though? The starter motor had turned the engine and the solenoid had engaged the Bendix to make the engine start. The way it is supposed to work. Then, just the motor was spinning without the Bendix engaged. That to me means starter solenoid malfunction.

I could hear the starter relay under the dash clicking which while it doesn't mean it isn't sticking, doesn't point to it as the problem either.

I carry a spare starter I rebuilt a year ago in the back of the 1009. My mission Saturday was to fix all the wiring, drop the thought to be bad starter, test the system out with no starter installed and then put in my spare.

I was able to find a 10' roll of 12 gauge fusable link wire at our local Car Quest along with crimp on ring terminals just in case I didn't have enough already in my electrical kit. $10 spent.

Attached is a picture of all the burned links I cut out sitting next to each other. Once I had them all cut off, I got out my yellow crimp butt connecters and found they don't fit 8 gauge wire. Another trip to town and I found Car Quest part number SST80. That is a 10-12 gauge crimp butt connector that comes with no insulation. Just the way I like them. $2.00 spent.

Back home and everything got wired back up. The other attached pictures show the replaced fuseable links. They are clean, light blue and have red/pink shrink wrap on them. Yellow cover end terminals too. Pretty much the pictures show you which wires will burn if you just pull the front battery negative terminal during a runaway starter event.

I pulled the starter and made sure the power in wires weren't touching anything. I had Colton get inside once I hooked up the batteries and try the key. No voltage to the purple solenoid wire unless he was turning the key to start. Off and on half a dozen times. All working good. Has to be the starter solenoid.

I put a DVOM on the solenoid and could not find conductivity between the main power in to the solenoid and the power in from the solenoid to the starter motor. Hmm. I thought that was it for sure.

I hooked up some jumper cables, put my foot on the starter and used a screw driver. Worked perfect. Bendix popped right out and the motor spun right up. Again and again and again. Thats not right.

I tested my carry around with me spare and it did nothing. Good thing I didn't need it.

I had another spare and it tested great. I installed it and the truck fired right up. Except, the voltage meter stayed right at the yellow/green line. Now what?

I turned it off, checked everything with the alternators and it looked ok. Batteries 12.4/12.5 engine off and 13.7/13.7 with the engine running. It starts and I can live with a low charge just driving around town. One entire day spent fixing this thing and I still didn't know what failed, why or if my alternators got zapped in the regulator some. At least it runs and I can drive to work Monday.

This morning I checked the batteries and 12.7/12.7 what what I found. Fired it up and the needle went to the middle of the green. 14.4/14.4 on the batteries with the engine running. All good.

I still think it is the solenoid that failed. However, since the starter ran for at least 1 minute if not more. It might have smoked itself some. Back to the rebuilder it will go next week. Along with my thought to be good spare starter.

Sorry for the long post, but I wanted to cover all the facts and relay what was done. The lesson here is that nothing is for sure ok and pulling just one battery cable will cause troubles.

Attachments

-

57.5 KB Views: 112

-

65.2 KB Views: 112

-

65.4 KB Views: 115