- 165

- 173

- 43

- Location

- Los Angeles/CA

I am having overheating problems with my 1009, and would appreciate any help.

It has a new badger diesel rebuilt IP, new injectors, and starts right up even in sub-freezing weather. The engine runs great, sounds great, and makes good power. But if its hot outside (>90F) or if I try to pull long highway grades the engine coolant rapidly warms to 220F and would probably continue to rise if I didnt get out of the throttle. EGTs are 500-800 cruising and eventually climb to 1000F or so on long steep grades.

If its warm out then I hit 215F coolant temp long before 1000F EGT and I need to slow down or sometimes pull over. If its cold like it has been recently (60F air temp) then I hit the EGT limit and water temps stay around 210F or just a bit under. But even that seems too hot to me and it wont stay winter forever...

I have temperature gauges in the radiator inlet and outlet and maintain a 20-30F delta at all engine operating conditions. Around town and on flat sections of highway when it is cold the radiator inlet temp is 195-205F and the outlet is 170-180F. When climbing steep grades, or even cruising 70mph on flat ground when its hot out the inlet temp rises to 210-220F and the outlet temp goes to 195-205F if I stay on the throttle. With the water coming out of the radiator already at the maximum 205F operating temperature, there is obviously no hope of keeping the engine at a safe temperature. Based on this data I am assuming the engine is creating more heat than the radiator can shed.

The radiator was installed new by me a couple years ago, and the truck has this problem whenever I drive on highways in the summer. I usually just drive around town and have been careful to slow down and not overheat when on the highway, but I really want to get it fixed now. Do I just need a bigger radiator? The stock mechanical fan and shroud are installed and in good condition, and the engine runs at thermostat temp (195-205F) at idle and at low throttle. It only overheats under heavy load on the highway or off road.

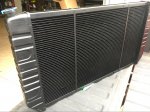

My current radiator is a 2 row 1.75" thick aluminum core, from rockauto (https://www.rockauto.com/en/moreinfo.php?pk=3606795&cc=1050589&pt=2172&jsn=1)

I have seen many posts on here about a copper/brass "CU850" radiator, but when I search that part number all I find is a Spectra Premium CU850, which is a 2 row plastic/aluminum radiator with a 2.375" thick core

I really dislike Jegs, but they also carry a radiator that looks like it would be a direct fit for the stock rubber insulators/brackets and has a 2.5" thick 2-row core (https://www.jegs.com/i/JEGS/555/511457/10002/-1)

What radiators are folks on here using successfully? Will going from a 1.75" to 2.375 or 2.5" thick core in my truck increase cooling capacity significantly? It seems like it would?

It has a new badger diesel rebuilt IP, new injectors, and starts right up even in sub-freezing weather. The engine runs great, sounds great, and makes good power. But if its hot outside (>90F) or if I try to pull long highway grades the engine coolant rapidly warms to 220F and would probably continue to rise if I didnt get out of the throttle. EGTs are 500-800 cruising and eventually climb to 1000F or so on long steep grades.

If its warm out then I hit 215F coolant temp long before 1000F EGT and I need to slow down or sometimes pull over. If its cold like it has been recently (60F air temp) then I hit the EGT limit and water temps stay around 210F or just a bit under. But even that seems too hot to me and it wont stay winter forever...

I have temperature gauges in the radiator inlet and outlet and maintain a 20-30F delta at all engine operating conditions. Around town and on flat sections of highway when it is cold the radiator inlet temp is 195-205F and the outlet is 170-180F. When climbing steep grades, or even cruising 70mph on flat ground when its hot out the inlet temp rises to 210-220F and the outlet temp goes to 195-205F if I stay on the throttle. With the water coming out of the radiator already at the maximum 205F operating temperature, there is obviously no hope of keeping the engine at a safe temperature. Based on this data I am assuming the engine is creating more heat than the radiator can shed.

The radiator was installed new by me a couple years ago, and the truck has this problem whenever I drive on highways in the summer. I usually just drive around town and have been careful to slow down and not overheat when on the highway, but I really want to get it fixed now. Do I just need a bigger radiator? The stock mechanical fan and shroud are installed and in good condition, and the engine runs at thermostat temp (195-205F) at idle and at low throttle. It only overheats under heavy load on the highway or off road.

My current radiator is a 2 row 1.75" thick aluminum core, from rockauto (https://www.rockauto.com/en/moreinfo.php?pk=3606795&cc=1050589&pt=2172&jsn=1)

I have seen many posts on here about a copper/brass "CU850" radiator, but when I search that part number all I find is a Spectra Premium CU850, which is a 2 row plastic/aluminum radiator with a 2.375" thick core

I really dislike Jegs, but they also carry a radiator that looks like it would be a direct fit for the stock rubber insulators/brackets and has a 2.5" thick 2-row core (https://www.jegs.com/i/JEGS/555/511457/10002/-1)

What radiators are folks on here using successfully? Will going from a 1.75" to 2.375 or 2.5" thick core in my truck increase cooling capacity significantly? It seems like it would?

Last edited: