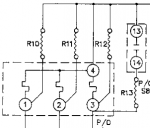

Check your K8 and S8 and S6 like you say you will. Sounds like a plan. The S6 only switches to the front panel gages what you want to read as indicated on the front panel, and has nothing to do with your issue. If that circuit is working, leave it. Make it clean, cool stuff.

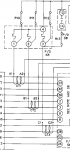

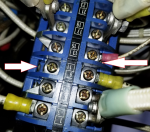

Just to think a moment about an area you have not mentioned; connect that 4KW load and after a warm up, apply that load. You say it will run forever that way. Now get a meter set to read AC Voltage. Measure the voltage on each active phase across the K1. (Phase L3 input to L3 output on the K1 for example) do you get a voltage drop? You shouldn't. If no drop go to the next item. If so, shut everything down, and do some K1 PM by burnishing those main contact pads inside. A Voltage drop increases your current draw and it gets worse with time, sometimes a very short time. In one class I had a 60KW 400HZ gen start the class all good and half way thru, it actually blew the top off the contactor. Turbine gens running you don't hear a lot. Usually contact pitting and sizzling shows up when loads are on when the K1 is engaged. Power companies use special circuits when applying power to a grid after an outage. The 802 has none. Minor pitting is normal.

The S8 does the same thing and is usually in place before starting the gen, but cleaning that puppy is a real pain. I usually moved the switch position several times until it stopped making any grinding noises while the gen was all OFF. One Soldier switched it while running once. Only once, Poof! Usually this does the trick setting contacts well together. I was successful in taking it apart and getting it back together again cleaning contacts from dirt , but you need patients. Lots of it. I was also among the few to do that. I do not recommend doing it so switching a little usually works. Cool?

The K8 is riveted together(some original K8s were screwed together), and is sometimes flakey in its operation. Most of the time you find it corroded inside and the coating on the inside resistors is flaking off from age and heat and I'll never know how the bugs get in there. External connections can also be no longer the best from vibration on an 802 and then the external relays could have issues. This and the The military uses wash racks and they never listened to "Don't Use that High pressure hose in there" . Old water intrusion is possible and you may also find condense water signs. Sometimes with an inch of water in the control box they tried to see if it still worked and after all it will dry better that way I was told, all was still wet; and then we usually got a call as it went Poof. Try your best and I believe you will be successful, just be safe. It would be nice to know what you found. Oh, also loose load terminals do the same thing, a loose connection does funny things. Overload is 110% so you are talking a new K8 will pop at 5, 500 watts, or supposed to . Some don't. If you ,after all the work, find nothing, (yes you will find something if only a fried bug and pitted contact points in the K1 or K8 inside resistor value change) and it functions well at 4000 watts on running, you still have a great gen and it also keeps things working well testing it at 4000 watts if you have to wait a while to obtain a good K8. TQGs were designed to run at over 70% load but no more than 90% allowing room for inductive reactance allowing the heater fan to turn on. A 5000 watt pure resistive load, is at the top. As parts get older they may no longer be at 100%. Think, your glass only holds 15 ounces and the beer is at the brim, and making foam with a sip is still in the can to your 5000 watts. Will it still run your load as you require when the lights go out?