- 1,308

- 1,681

- 113

- Location

- Basehor, KS

S1 2, 4, 6, 8 should have 24V as soon as S10 is in "Normal" Position AND S17 E-Stop is Pulled Out AND CB1 is not tripped.I finally had some time to get back to debugging the electrical issue.

I have verified all the correct voltages are on S1, depending on position of switch. I have 24V on S1 - 2,4,6,8 when S1 is in the start position I get 20V on pin 7, I followed that to K12 (Engine Fault Relay) pin 8 to pin 2 (N/C) should have 20V, and this is where the first problem appears. When I go through the start sequence the first time, from off to prime to start I get 19V at pin 2 to but no start, as soon as I release I get the oil pressure error light and K12 is energized and no power at pin 2. I clear the error, but it does not de-energize K12. I have to put the S1 back in off position and start over again.

K12 get power on Pin A which comes from S7-pin 7 as well as Pin 4 of K12 which is normally open until K12 is powered. Obviously the power is not coming from S7-7 so it coming from K12-4 which creates a lockout condition thus the reason you have to remove all power to reset. Pin 4 is connected to Pin 7 which is connected to S14-7 (crank disconnect switch), K19 (fuel level relay) pin A ( Power for relay)

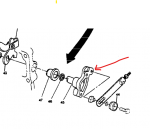

In order for power to get to the starter L4, the power signal also goes through K16 (Crank Disconnect Relay) and K2 (Crank Rely) I know K2 works since S10 Dead Crank works. Looking at K16 the only way the signal gets through, it has to be energize when switch S1 is turned to start, this relay does not energize until after the S1 is released. Which means the power to A and B pins on K16 are not getting power at the right time. Pin B (ground) is connect to S14-1 and Pin A (positive) is connected to K20-4 K20-9 (oil pressure relay), and K12-1 so any of those relays can provide 24V.

I am at the point where can someone tell me how do you check S14 that it is working properly. I looked at it and do not see any obvious failures. Since the fuel level relay is in the circuit, how much diesel must be in the tank, I only put in a couple of gallons, did not want to fill it until I new it was running. The other possible fault is oil pressure, I put enough oil in it and check it a couple of time and it all the way up on the dip stick. As said before if I dead crank it for a little be before trying to start it do not always get the oil pressure fault light. Lastly, and you might have noticed the voltages, going through S1 the voltage drops from 24 to 20V and as the signal goes through the relays it drops to 19volts. This definitely is not normal. not sure of the drop in S1 it could be due to the diode across pin 7 to pin 1. can someone verify what is correct.

Just an FYI, I put a starter button on the L4, while holding S1 in the start position I pressed the stater button and the engine turned over but did not start. this tell me something is disabling the starting.

Any insight where to look next.

Further, S1 Pin 7 will be technically at the level of the Battery during crank. Since you are measuring 20V and you have a no crank condition, the Voltage should be higher, around 24V or whatever your system is at based on battery charge status.

This sounds to me more like an issue with S1

I would do the following:

Set S1 to run prime and make a momentary jumper from S1-2 to S1-7

If starter engages, remove jumper and set S1 back to OFF => S1 is your problem

If starter does not engage then the problem is somewhere else

Last edited: