IMHO: block, battery, fuel, oils. In that order as temps get colder.

The cold advance on the IP and fast idle is set to 100F water temp. If you can get your block above that, it will be quieter when it starts (advanced timing is louder).

Much below 32°F/0°C and batteries will not be able to convert stored chemical energy into electrical charge fast enough to overcome draws, which will result in lower cell and thus battery voltage. DC series wound motor RPMS are directly related to voltage, less volts means slower speeds and more friction. More friction mean higher current, and longer cranks, which leads to burned out starters and possibly welded starter relay contacts. Get those batteries warm before starting and it'll start easier - if you're going to power a battery warmer, might also look into a battery maintainer or charger to top them off too (charged batteries are less prone to freezing!!).

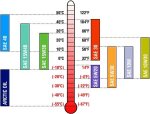

Straight #2 Diesel has a cloud point of between 23°F/-5°C and -18°F/-28°C, which is where the paraffin wax starts to crystallize in the fuel - eventually it'll plug up the filter and will starve the engine for fuel. Winter blends push in #1 diesel (which is essentially pure Kerosene) which has no paraffin in it to come out of solution and crystallize. This doesn't eliminate the paraffin content, it merely dilutes it so that there isn't enough paraffin content to consolidate. JP-8 is basically pure Kerosene Diesel #1, and it's what DoD is using under their Single-Fuel Concept initiative (when you only use one type of fuel you can carry more of that one and share it across all your equipment).

Interesting read here that has to do with CUCV (6.2L/6.5L engine) testing... There are fuel filter heaters available (aftermarket), but you can also put a patch heater on the tank and circulate fuel with a little electric lift pump to circulate the warmed fuel through other components (like the filter, IP, return line, etc...).

When you get much colder than -10°F/-23°C, you need to start worrying about your lubrication oils too. Below certain temperatures your oil won't work the way it's supposed to with respect to reducing friction. A change-out in the fall and one in the spring at a minimum to match the service temperatures to the seasonal ambient range will keep the operating ranges of the oils "happier".

If you really plan on going into cold, like running through the snow etc, you might consider the arctic heater setup for the CUCV which warms the oil pan and transmission sump and transfer cases. If you don't want to put on the military heater kit due to its space claim under the hood, you can again go with patch heaters (they come in 12/24V too) and put an insulating pad over that to keep the cold snow away from your pans. Also worth thinking about is what happens to metal when very cold oil is pushed into a warm/hot block - you will get localized contraction of the metal, and if the temperature difference is severe, you could actually crack things (cold oil squirted on the tops of hot valves... yeesh). In Alaska where it's properly cold, these are common at public shopping centers to keep engines warm rather than running them at idle to keep them from freezing up:

Another thing to not forget when getting your truck ready for cold, is the freeze point of your coolant. Summer mixes of 55%-coolant/45%-water will freeze at -25°F/-32°C (will start to slush up within 5 degrees of the freeze point, so watch out), winter mixes of 66%-coolant/33%-water will freeze only when it gets below -70°F/-56°C. Coolant should be changed every year OR tested for freeze point and anti-corrosion additive quality. I get the impression that if you run your truck in the cold of an icy winter and a hot summer every year, having two batches of premixed coolant concentrations would be worth it.