ramdough

Well-known member

- 1,554

- 1,729

- 113

- Location

- Austin, Texas

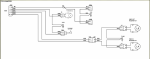

I have an A0 winch with the harness from that.

I am installing on an A1 truck. Instead of wiring into my truck harnesses, I am proposing rewiring it to be always hot. I took a crack at the wiring schematic.

Will post next post the pictures.

@Ronmar any thoughts? Anyone else?

Sent from my iPhone using Tapatalk

I am installing on an A1 truck. Instead of wiring into my truck harnesses, I am proposing rewiring it to be always hot. I took a crack at the wiring schematic.

Will post next post the pictures.

@Ronmar any thoughts? Anyone else?

Sent from my iPhone using Tapatalk