- 2,112

- 555

- 113

- Location

- Davis County, UT

In 2013 I replaced my failed, stock 6TL batteries with a pair of Group 31 batteries from NAPA P/N: 7235.

http://www.steelsoldiers.com/showthread.php?124577-Electric-problem&p=1551667&viewfull=1#post1551667

For over 3 and 1/2 years I used a single ratchet strap to hold down the batteries. This early spring I noticed that part of the strap had melted - likely due from a battery spark, or acidic gasses. I decided it was past time to replace the poor, temporary solution with something better.

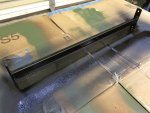

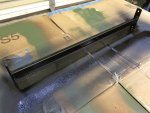

I've used an 11 gauge, 1/2" x 1" rectangular tube and welded 4" of 1/8" thick x 1" wide flat to the end (flush with the "top" of the flat). The over all rod length is 23-1/8". The 1/4" holes are drilled at 1/2" down and 1/2" in from either end of the flat (3" separation), then matching holes were drilled off the center of the metal battery box (I measured the box at about 13-3/8" wide, so the holes were placed at 5-3/16" and 8-3/16" from the front, 1-1/16" down from the top, as these group 31 batteries are 8-1/2" tall).

I have yet to cut some wood to fill the leftover side-to-side space in the battery box. A length of 2x4 (side ways) would be just about perfect, but I may need to cut some different wood as I'd like a tight fit. The third battery is for the 12V alternator and 12V accessories. The 12V dedicated battery is a bit shorter than the others, so I am going to add sections of a rubber mat below the bar (or under the battery) to make up the difference.

I used self etching primer, Krylon flat black, and then Plasti-Dip to rubber coat the center bar.

[HR][/HR]

A little bit of background and disclosure. This was actually the very first project that I've welded. In late 2013 I took a local 15 hour "Hobbyist Welding for Beginners" class. Last year, I purchased a very nice Millermatic 211 with cart, and then later, a CO2/Argon tank.

This year I purchased a 25' extension cord for the welder, that I was even able to add text down the length of it (for security reasons). I put my name, telephone and email address. (Both red and blue options for those who might care about the color of their welding equipment).

https://www.amazon.com/gp/product/B016P7SGWK/

I practiced a bit on some free scraps to get used to my mask, gloves, and gun. Don't worry, I was already chastised by my brothers for "improper" practicing by not cleaning the paint and rust from the scraps first. The reason I am posting all this is to help and encourage others to "start somewhere". It doesn't matter where you start, only that you start and keep going.

I had one of my brothers, who's well practiced in welding, weld one end of this rod, so when I went home and attempted my first welding project on my own, I would have a good reference.

I think I did pretty good, even if I didn't have a "proper" welding table:

http://www.steelsoldiers.com/showthread.php?124577-Electric-problem&p=1551667&viewfull=1#post1551667

For over 3 and 1/2 years I used a single ratchet strap to hold down the batteries. This early spring I noticed that part of the strap had melted - likely due from a battery spark, or acidic gasses. I decided it was past time to replace the poor, temporary solution with something better.

I've used an 11 gauge, 1/2" x 1" rectangular tube and welded 4" of 1/8" thick x 1" wide flat to the end (flush with the "top" of the flat). The over all rod length is 23-1/8". The 1/4" holes are drilled at 1/2" down and 1/2" in from either end of the flat (3" separation), then matching holes were drilled off the center of the metal battery box (I measured the box at about 13-3/8" wide, so the holes were placed at 5-3/16" and 8-3/16" from the front, 1-1/16" down from the top, as these group 31 batteries are 8-1/2" tall).

I have yet to cut some wood to fill the leftover side-to-side space in the battery box. A length of 2x4 (side ways) would be just about perfect, but I may need to cut some different wood as I'd like a tight fit. The third battery is for the 12V alternator and 12V accessories. The 12V dedicated battery is a bit shorter than the others, so I am going to add sections of a rubber mat below the bar (or under the battery) to make up the difference.

I used self etching primer, Krylon flat black, and then Plasti-Dip to rubber coat the center bar.

[HR][/HR]

A little bit of background and disclosure. This was actually the very first project that I've welded. In late 2013 I took a local 15 hour "Hobbyist Welding for Beginners" class. Last year, I purchased a very nice Millermatic 211 with cart, and then later, a CO2/Argon tank.

This year I purchased a 25' extension cord for the welder, that I was even able to add text down the length of it (for security reasons). I put my name, telephone and email address. (Both red and blue options for those who might care about the color of their welding equipment).

https://www.amazon.com/gp/product/B016P7SGWK/

I practiced a bit on some free scraps to get used to my mask, gloves, and gun. Don't worry, I was already chastised by my brothers for "improper" practicing by not cleaning the paint and rust from the scraps first. The reason I am posting all this is to help and encourage others to "start somewhere". It doesn't matter where you start, only that you start and keep going.

I had one of my brothers, who's well practiced in welding, weld one end of this rod, so when I went home and attempted my first welding project on my own, I would have a good reference.

I think I did pretty good, even if I didn't have a "proper" welding table:

Last edited: