Kenny wrote:

Should we have a significant injector problem on the other half of the engine, we could have soaring EGTs and potential disaster and know nothing about it until disaster strikes.

This was why I installed my probe after.There were other reasons: the probe runs cooler(longer lifespan?) and can't go thru the turbine(OMG), though I feel both are very unlikely. The switching of probes is a good way to save $ and it has been done in racing for decades. The probe works on very low voltage(0-35 millivolts) so good switch may be needed (i.e-gold plated contacts).

The web site below is probably the best, and most experienced, of the turbo kit companies. It is loaded with good info. I couldn't find a coypright mark so here is the part on probe location.

Whether the pyrometer thermocouple is mounted before or after the turbine is usually a matter of finding a suitable mounting location, or of convenience. It should be noted that when the EGT is measured after the turbine, the turbine outlet temperature at full throttle or under a heavy load typically would be 200º to 300º F. lower than the EGT measured in the exhaust manifold. The temperature drop after the turbo indicates the amount of heat energy in the total exhaust gas flow that was used to drive the turbocharger. The temperature drop through the turbine is also related to the total flow and speed of the flow through the turbo. At part throttle, under light load, such as cruise conditions, the turbine outlet EGT may be as much as 500º F. lower than the turbine inlet temperature, but the total exhaust flow is much less than at full throttle. At high turbine speeds (under heavy load) the exhaust gases simply don’t have time to give up as much heat energy as they speed through the turbine. This variance is why installation of the thermocouple in the exhaust manifold is considered more accurate.

http://www.bankspower.com/Tech_whyegt.cfm

I wonder if the last line holds true for the LD/LDT/LDS exhaust manifold.

The 500*F difference across the turbo part, offered the context of, " part throttle, under light load", is also very interesting. I see my EGT fall rapidly under these conditions. I don't think my pre turbo EGT is excessive here, but a second probe would be nice.

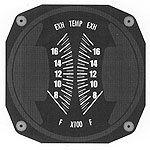

I am sure of this. Having a way to monitor EGT is important. A properly designed system may never have a problem but then sometimes settings change. Other times more performance is desired. A pyrometer will let you take more without risk. JimK