I do not agree with advice given regarding capping front service and emergency lines.

The advice given was not to cap the service and emergency lines, it was to de-install them COMPLETELY and cap the ports where they were connected to their respective checkvalves...

These are supply lines. They both take air from the vehicle ahead and feed it to the input of two separate check valves respectively.

In the case of the emergency line it feeds a “T” fitting that then feeds a one way checkvalve that feeds air into the main air system between the air dryer and the wet tank. The other side of the “T” feeds a 2 way check valve input in the park brake circuit. The other side of this 2 way checkvalve is fed from the system park supply valve... when air is fed into the emer line it sets the park brakes and feeds air into the tanks on the towed vehicle.

The service gladhand is similar in feeding a “T” fitting. The outputs of this “T” feed input ports on two separate 2way check valves. The other input on these 2 way checks is fed by the primary and secondary outputs of the brake pedal foot valve. When air is applied to the service gladhand it applies air to the brake system the same way it is applied when you step on the brake pedal in the vehicle

Stealpeak in your case, I would suspect that the one way check where emer air is input between dryer and wet tank is leaking system air back into the front emergency line. If the emer gladhand is plugged, this leakage will build pressure in the line back thru the other leg of the “T” to feed pressure into the input of the 2 way check valve which applies park brake pressure the same way the system park supply does to the other side of that 2 way valve. Quick check for this would be to put a guage on a gladhand fitting and connect it to the front emer gladhand. Start the truck and if you see pressure building on that gauge well then there is your answer...

Removing the front service and emergency lines and their “T” fittings completely and capping the ports AT the checkvalves, removes possible leak areas and removes that possible pathway for leakage into the emergency line that would set the park brake if the emer gladhand is plugged...

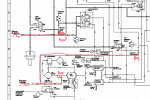

TM9-2320-365-20-1 pneumatic schematic drawings start on page 1691