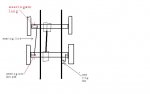

Any time I've seen that linkage, the drag link from the front to the rear has been on the same side as the steering gear. I think to limit the number of "links" in the chain between the steering gear and that last tire to recieve "input".

Just for consideration, (I am not claiming to have seen a lot of these, nor am I claiming to be an engineer...), but if the front axle were stock, and the "new drag link" to the rear axle were added to the original steering arm, on the front axle, outboard from the original drag link to the steering gear, then would that not give you the same geometry change that you need while only modifying/custom making one single arm, as well as "somewhat" branching the system so that every ball joint does not get the wear from being beaten on by every tire?

Just thinking out loud... Take it for what it's worth.

has anybody done this yet???

has anybody done this yet???