If you look up at the air pack, the air line that pressurizes the air pack comes from the back and attaches on the frame rail side of the valve assembly that is ahead of the air piston. This line has no other connections and is likely to be a straight fitting into a 90 degree fitting on the side on the end of the air valve assembly on the air pack. This is closest to the frame. As I said, it goes straight back along the frame to the air tank.

The other air line connections on the frame rail side include the slave air connector for the trailer on what would be the "front" of the air valve, an exhaust line that heads up and towards the air cleaner area from an angle fitting that is closest to the main body of the assembly, and the J-Tube which connects the air valve to the back of the air piston assembly.

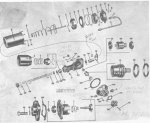

I have rebuilt many of these and the common problem is gunk getting into to the actuator for the air which can get siezed up and you are left with only the braking you can create with your foot on the master cylinder. Another common issue is that a leak occurs and as the brake fluid leaks out moisture gets into the system and migrates down from the master cylinder into the air hydraulic unit specifically into the compensatory valve. This causes rusting and deterioration of the bore that this valve is in along with the main bore of the slave cylinder.

For information, the master cylinder creates about 500 PSI of pressure, and the air hydraulic boosts this to upwards of 2000 PSI. When the air hydraulic booster is off line, you have very little braking and operating a truck this big without adequate braking is extremely dangerous.

If you can get your hands of them, the following TM's are helpful

T M 9 - 2 3 2 0 - 2 0 9 - 2 0 - 3 - 2

Contains the R and R instructions and indentifies the connections to the unit.

TM 9-2320-209-34-2-1

Contains the rebuilding instructions for the airpack assembly.

I know that the Old Steel Soldiers site is down so you will have to be resourceful in locating these two TM's.

RL