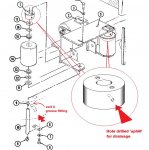

M816 rear winch "Roller ponding" - Fix

Had forgotten to post these from some time ago. My solution was to extend the grease fitting then caulk the void:

I/Fittings. II/Fittings installed in roller. III/Roller test fit in frame. IV/Cap in place. V/Masked nipple for painting (Nipple will be yellow)

Another point: Grease capacity is enormous. And wastefull. There ought to be a 'communication' sleve below the top taper roller bearing #15 and the bottom taper roller bearing #13 [Pic in post #5] to blank off the massive void in each roller. Carefully measured though so as not to preload the bottom bearing.

NOTE. When disassembling, index parts for location and orientation. When I reassembled mine, I hadn't done this (I thought that this was too low tech) but now even though all the rollers partially spin by hand but bind in a couple of spots. Not yet loaded and run as Jeff suggests, I am still rebuilding/modifying the level wind - but that's another story.... But loaded operation will probably 'seat' everything and fix the issue.