Hollndr

New member

- 21

- 0

- 1

- Location

- Twin Lake/ MI

Hello all, been searching the technical manual and through threads for a solution to my issue but have yet to find it, if I missed it please point me to the right direction. Sorry if this has been covered, i'm new to military trucks.

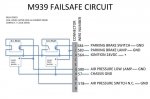

I Have an '85 M931 A1 with ABS, about 1200 miles since 2010 gov rebuild. Recently had an issue where my rear brakes locked up on me and would not release. I was backing up to a trailer (pintle hookup). Upon hooking up and driving away the truck felt bogged down. Unhooked the trailer and pulled forward a little and truck completely locked to where it wouldnt move. Messed with the parking brake in and out as well as the maunal brake switch on the dash. Air pressure for primary and secondary tanks were both over 120psi with no drop in pressure over time. Had to have a tow truck come and they were able to get the brakes to release by messing with the parking brake switch and manual brake button on dash. Tow truck owner told me the parking brake switch sets both the parking brake on the driveshaft as well as the drum brakes, but was not releasing the drum brakes when the parking brake was released. Said I may need to replace the parking brake switch, could be going bad. Drove probably another 100 miles or so with no issue until I went to hook up trailer again and brakes locked up again. Messed with both parking brake and manual brake, draining and re-pressurizing air system and couldnt get it to release. Walked away for a couple hours and when I came back the brakes had released and I could move it again. Went to drive the truck and seemed to drive ok but felt a little under powered. About 2 miles from my house at about 55mph my low air alarm / light went off (air pressure on guages both over 120psi). pulled over, backed up (alarm went off) and drove back home. drums felt a little warm for the little braking I did.

Im uncertain as to what may be happening here and wondering if anyone has had this issue and your fix (is it the parking brake switch?) or if anyone whos more knowlegable than me may be able to point me in the right direction. Thanks in advance for any of your help!

I Have an '85 M931 A1 with ABS, about 1200 miles since 2010 gov rebuild. Recently had an issue where my rear brakes locked up on me and would not release. I was backing up to a trailer (pintle hookup). Upon hooking up and driving away the truck felt bogged down. Unhooked the trailer and pulled forward a little and truck completely locked to where it wouldnt move. Messed with the parking brake in and out as well as the maunal brake switch on the dash. Air pressure for primary and secondary tanks were both over 120psi with no drop in pressure over time. Had to have a tow truck come and they were able to get the brakes to release by messing with the parking brake switch and manual brake button on dash. Tow truck owner told me the parking brake switch sets both the parking brake on the driveshaft as well as the drum brakes, but was not releasing the drum brakes when the parking brake was released. Said I may need to replace the parking brake switch, could be going bad. Drove probably another 100 miles or so with no issue until I went to hook up trailer again and brakes locked up again. Messed with both parking brake and manual brake, draining and re-pressurizing air system and couldnt get it to release. Walked away for a couple hours and when I came back the brakes had released and I could move it again. Went to drive the truck and seemed to drive ok but felt a little under powered. About 2 miles from my house at about 55mph my low air alarm / light went off (air pressure on guages both over 120psi). pulled over, backed up (alarm went off) and drove back home. drums felt a little warm for the little braking I did.

Im uncertain as to what may be happening here and wondering if anyone has had this issue and your fix (is it the parking brake switch?) or if anyone whos more knowlegable than me may be able to point me in the right direction. Thanks in advance for any of your help!