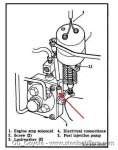

mine was the same way. it turns out the problem was the linkage was binding on the solenoid. It took some careful bending and filing the hold the linkage goes through to make it fit better. I think this is a common issue with these sets. When I first got mine from GL and brought it home I did all the PM. Changed the oil, all the filters, blew the lines out etc. It was a new rebuild with only 2 hours, but I wanted to be sure things looked good. Anyway, when I went to start mine, it did not start. I knew it had to be something simple and it was. That linkage was binding. So while I cranked it over, I move the governor linkage and it fired right up. Be sure to check the Hz gauge to make sure the engine speed is correct. After you fire it up. Also check oil pressure to be sure it is within range.