GASCANS001

Member

- 38

- 48

- 18

- Location

- Fairmont West Virginia

I have made a post prior to this on fixing up my 003 for my step dad

I’m continuing to fight this issue.

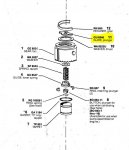

This set has 236 hours not on rebuild. It’s a 92 model I believe. The issue at hand is it’s a dog to start. Spray a good sniff and it’ll take off but with out it, it will not. Once it pops off it’ll run for maybe 30 seconds and it stalls out. (Appears once it gets a little heat inside of it it shuts off and will not restart ) I’m getting a ton of white grey blue smoke. I replaced the head gasket as it was blown, Sent the injectors off to Area Diesel Service to get rebuilt, and completely rebuilt the fuel system (new lines, new pump, spin on filter adapters with Wix 33528, Wix 33405) and after the head gasket and injectors it’s worse.

Before I send this injection pump off does anyone have any other checks they recommend?

It’s worth noting I did set the valves according to the tm. Also the injector nozzles were so bad ADS made new ones. I know the tank is extremely dirty sp I by passed it from day one.

Im getting drips from the return line I would think it would be more of a stream which is why I Feel like it’s an IP issue.

What are your thoughts?

I’m continuing to fight this issue.

This set has 236 hours not on rebuild. It’s a 92 model I believe. The issue at hand is it’s a dog to start. Spray a good sniff and it’ll take off but with out it, it will not. Once it pops off it’ll run for maybe 30 seconds and it stalls out. (Appears once it gets a little heat inside of it it shuts off and will not restart ) I’m getting a ton of white grey blue smoke. I replaced the head gasket as it was blown, Sent the injectors off to Area Diesel Service to get rebuilt, and completely rebuilt the fuel system (new lines, new pump, spin on filter adapters with Wix 33528, Wix 33405) and after the head gasket and injectors it’s worse.

Before I send this injection pump off does anyone have any other checks they recommend?

It’s worth noting I did set the valves according to the tm. Also the injector nozzles were so bad ADS made new ones. I know the tank is extremely dirty sp I by passed it from day one.

Im getting drips from the return line I would think it would be more of a stream which is why I Feel like it’s an IP issue.

What are your thoughts?