DonaldB

New member

- 12

- 0

- 0

- Location

- Ontario,NY

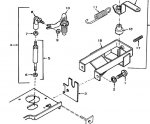

Item number 5 page 133 of TM5-6115-585-24P (LINKAGE,GOVERNOR), seems to have a lot of free play (the #6 side of the Linkage seams to just go in and out of the assembly) and the rest of the linkage doesn’t move. Is this some sort of gas shock or something? The generator cranks but won’t start.

Attachments

-

52.4 KB Views: 22

Last edited: