- 10,349

- 94

- 48

- Location

- Meadows of Dan, Virginia

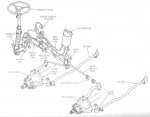

Question for you 5-ton guys, if you put the front wheels off the ground, how hard is it to turn the steering wheel without the engine/pwr steering running?

I'm trying to find out what's "normal". My 8x8 with two axle steering is extremely hard to turn and the ball joints are very tight, just can't believe it's supposed to be that way. (My truck hasn't been driven yet) I can't imagine that it would be possible to keep going straight if the caster effect of the wheels has to fight this.

I have one of the tie rod ends off, but can't find any spec on the torque required to turn the ball in the socket (mine is like 50-70 ft-lb)....

Thanks,

I'm trying to find out what's "normal". My 8x8 with two axle steering is extremely hard to turn and the ball joints are very tight, just can't believe it's supposed to be that way. (My truck hasn't been driven yet) I can't imagine that it would be possible to keep going straight if the caster effect of the wheels has to fight this.

I have one of the tie rod ends off, but can't find any spec on the torque required to turn the ball in the socket (mine is like 50-70 ft-lb)....

Thanks,