USMC6062

Member

- 371

- 1

- 18

- Location

- St Augustine, FL

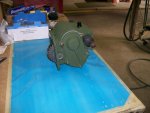

I have been going through my winch setup that's going on my truck here real soon. I have all my parts done and ready to go on. I took pictures along the way, and figured I should share them with ya'll. I have more of the winch itself I will post later.

Attachments

-

78.7 KB Views: 211

-

73.6 KB Views: 194

-

75 KB Views: 194

-

69.6 KB Views: 186

-

96 KB Views: 198

-

97.2 KB Views: 202

-

76.9 KB Views: 204