Plane Fast

Member

- 408

- 3

- 18

- Location

- Panama city FL

I went ahead and just started a new thread specific to the 939 series.

Well i finished and installed my Pulsetech PDU with solar panels.

I gave it a good solid week for a good test of the charging capability.

Did not go well!

History of my truck.

This truck has never had an issue with starting nor weak batteries. No matter how long I let it sit. Fired right up, with just a bump of the starter. (Month or more)

I drove the truck for about an hour before I parked it and finished the install.

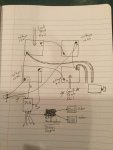

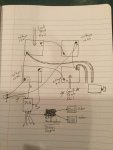

This is a rough diagram of my wiring.

Here are the components.

Although I'm using two small solar panels. Voltage was very good off both units.

The week long test had sunny sky's almost everyday.

Well, went to start the truck.... Nothing dead as a door nail!

Crap. So I checked voltage on the batts. All but one was good.

Hooked up my battery charger to the weak batteries and charged them up.

No dice. The lowest battery will not hold a charge over 9 volts and failed the load test.(#4)

So I disconnect the two weak batteries and tried to start on the two good ones.

It would just barely turn over. No start. I charged the batts longer and then use the start assist on my charger. Got the truck running. (Barely)

So I load tested all the batts. The #1 and #4 failed.

From my pic the batteries would be top 1 2, then bottom 3 4.

So now I have to figure out why it killed all my batteries. I find it hard to believe that the Pulsetech could short out two batts. I have all of it disconnected now. Not sure if I can get back the one batt(#4)

Guys with alternator knowledge. From looking at my wire diagram. Do you think it is possible that the one battery was failing and the charging system could not equalize the load? Because the two bad batteries are the first and last ones in the charging system.

Well i finished and installed my Pulsetech PDU with solar panels.

I gave it a good solid week for a good test of the charging capability.

Did not go well!

History of my truck.

This truck has never had an issue with starting nor weak batteries. No matter how long I let it sit. Fired right up, with just a bump of the starter. (Month or more)

I drove the truck for about an hour before I parked it and finished the install.

This is a rough diagram of my wiring.

Here are the components.

Although I'm using two small solar panels. Voltage was very good off both units.

The week long test had sunny sky's almost everyday.

Well, went to start the truck.... Nothing dead as a door nail!

Crap. So I checked voltage on the batts. All but one was good.

Hooked up my battery charger to the weak batteries and charged them up.

No dice. The lowest battery will not hold a charge over 9 volts and failed the load test.(#4)

So I disconnect the two weak batteries and tried to start on the two good ones.

It would just barely turn over. No start. I charged the batts longer and then use the start assist on my charger. Got the truck running. (Barely)

So I load tested all the batts. The #1 and #4 failed.

From my pic the batteries would be top 1 2, then bottom 3 4.

So now I have to figure out why it killed all my batteries. I find it hard to believe that the Pulsetech could short out two batts. I have all of it disconnected now. Not sure if I can get back the one batt(#4)

Guys with alternator knowledge. From looking at my wire diagram. Do you think it is possible that the one battery was failing and the charging system could not equalize the load? Because the two bad batteries are the first and last ones in the charging system.

Last edited: