- 48

- 28

- 18

- Location

- Hereford, Arizona

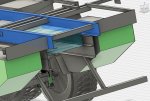

We have another question. We are designing a habitat for our M1083 and we have placed an access panel on the floorboard to gain access to the transmission in case it has to be removed. I can tell by looking at the transmission, that the four large horizontal bolts seem to be the primary transmission mounting bolts, but are there any other bolts that will need to be removed to lower the transmission, that can only be accessed from the top? We're designing the subframe and I don't want to install a crossmember someplace that will block access to any hardware we'll need to get to. Thanks

Kevin

Kevin