- 1,577

- 138

- 63

- Location

- Norwood LA

The purpose of this post is to document information on this trailer-mounted shelter that was recently being surplused by the USAF. I’ve searched the net and found no information, so if anyone has photos, TMs, etc., please let me know.

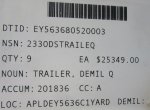

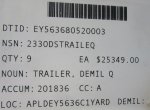

I won one of about 9 of these mobile microwave shelters from Eglin AFB sold through GP in April 2019. GP identifies the shelters as “S/A Enclosed Utility Trailer.”

The trailer and shelter have no manufacturer identification sticker or tag, but the AF has assigned a unit number that is painted on the trailer tongue. That painted unit number is the only identification that I've found on the 6-8 shelters I inspected. One of the vent fans has a date stamped 1984 but I don’t know if that is valid for the shelter.

TRAILER

Tires are mounted on 4-lug 16” rims and are either 7.00-16 LT NDT, 6.50-16 LT highway tread, or 225/75R16 commercial tires, and a large majority of the tires were dry-rotted to some extent. One shelter had a wider tire mounted, but the sidewall interfered with the spring pack grease zert to the point that the sidewall may have been gouged. Tire pressure is recommended at 40-50 PSI as per stencils. None of the trailers had fenders over the wheels. The single axle is a 1 ¾ inch square tube drop axle with a sliding spring pack. The trailer does have lights and surge brakes, so it may road worthy, but there were reports of heavy swaying at speeds over 45-50 mph. The trailer lights and 7-pin plug are 12-volt.

There are 3 jacks on the trailer that swing up for towing, two at the rear corners to be used for stabilizers, and the tongue jack. There is also a swiveling wheel on the tongue that can swing up and lock for towing. The tongue jack has a base extension welded to it, and the one I bought could only allow the pintle ring to lower to 24 ¾” to the bottom of the ring. This level was actually too high to allow the ring to drop into my truck pintle hitch, so I will probably replace the jack or cut off the foot extension.

The surge brake also has a rotating lever in front of the master cylinder that may act as a break-away lever, as well as a parking brake. The system was dismantled on my trailer, so I could not verify this.

The trailer is constructed of 5” channel iron, 4” channel iron for the tongue jack mount, and 1 ½ x 2 ½ in angle iron for the 4 corner braces under the box. The trailer dimensions are overall length 169 5/8” (not including the step bolted on the rear) and frame width of 83 3/8”. The overall axle width wheel hub to wheel hub is about 100.5” The aluminum rear step is attached to the frame with 9/16" stainless steel bolts and nuts.

I’m not sure what’s the purpose of the tall steel structure at the front of the tongue, but the top plate has 4 bolt holes, and may be a braced mounting point for an antenna mast.

SHELTER

The shelter is attached to the trailer at 4 reinforced mounting points using a clevis-head bolt.

The shelter dimensions are:

Outside box (not including the tiedown brackets)

Width 80 5/16”

Length 100 1/16”

Height 77 9/16”

Outside box (including the tiedown brackets) w/o clevis bolts & pins

Width 81 ¼”

Length 109 1/8”

Height 79”

Outside box (including the tiedown brackets) with clevis bolts & pins

Width 83" (other dimensions same)

Inside Box

Width ~75 ¾”

Length 96 3/16”

Height ~73 ½”

The wall thickness seems to be about 2”, constructed of aluminum frame and sheet. The only steel found on the shelter are the corner lift/tie down brackets and rings, some of the door hardware, roof access steps. Don’t know if the insulation is solid foam or fiberglass matt, or ?.

The floor is asphalt tile, with a floor drain with plug just to the right of the door.

The air conditioner is a Friedrich UE08D11C 8000 BTU Uni-Fit Series Room Air Conditioner with Electric Heat, 115 volts, and the freon has been removed from all the units I inspected (removal certification notice in some of the shelters). The AC is still available for about $630 from Amazon as of May 2019.

There are two vents to either side of the AC, and the shelters had none or one or two tubeaxial fans installed. The one in mine is labled NSN 4140-00-018-6535, made by Rotron, and dated 5-17-84.

Different shelters came with electronic racks or cabinets, but all seemed to come with a communication wiring array mounted to the passenger side of rear wall, with a cable to the wiring connector pass-through mount on the passenger side wall (supposed to have an inside cover but mine was missing). A lift-up door on the outside provides access to the wire connection points. The top hinge on this outside door on my shelter was frozen, and the pop rivits were broken, so when I removed the 4 bolts securing the door, it fell off. I’ve seen at least 3 variations of the wiring panel on the passenger wall.

Power to the shelter enters through the access port commonly found on other shelters (3 variations have been seen). Connections on mine are 4-wire female threaded plugs. On the other side of this port on the driver side rear wall is a breaker panel (I’ve seen 2 types of panels). Power supply is 120 volt, 30 amp, single phase. Lighting is 3 fluorescent light fixtures along the front and side walls. Empty fiberoptic cable raceways also travel along the ceiling.

The four corners of the roof are steel/iron with swiveling lift/tie down rings. Most, if not all of the shelters had 2 cables permanently mounted to the rings and interwoven loops formed at the middle for lifting. My shelter roof had a square patch sheet of aluminum in the middle, but there is no indication of roof access inside the shelter. This may be protection from lifting hooks or attachments hitting the roof during shelter lifts.

Another penetration on the upper front driver side wall is a 90 degree copper or brass hollow elbow, which is closed on the outside. Two holes marked V (verticle?) and H (horizontal?) are directly below the elbow. These will have to be plugged as they will let in rain.

More to come as I learn more....

I won one of about 9 of these mobile microwave shelters from Eglin AFB sold through GP in April 2019. GP identifies the shelters as “S/A Enclosed Utility Trailer.”

The trailer and shelter have no manufacturer identification sticker or tag, but the AF has assigned a unit number that is painted on the trailer tongue. That painted unit number is the only identification that I've found on the 6-8 shelters I inspected. One of the vent fans has a date stamped 1984 but I don’t know if that is valid for the shelter.

TRAILER

Tires are mounted on 4-lug 16” rims and are either 7.00-16 LT NDT, 6.50-16 LT highway tread, or 225/75R16 commercial tires, and a large majority of the tires were dry-rotted to some extent. One shelter had a wider tire mounted, but the sidewall interfered with the spring pack grease zert to the point that the sidewall may have been gouged. Tire pressure is recommended at 40-50 PSI as per stencils. None of the trailers had fenders over the wheels. The single axle is a 1 ¾ inch square tube drop axle with a sliding spring pack. The trailer does have lights and surge brakes, so it may road worthy, but there were reports of heavy swaying at speeds over 45-50 mph. The trailer lights and 7-pin plug are 12-volt.

There are 3 jacks on the trailer that swing up for towing, two at the rear corners to be used for stabilizers, and the tongue jack. There is also a swiveling wheel on the tongue that can swing up and lock for towing. The tongue jack has a base extension welded to it, and the one I bought could only allow the pintle ring to lower to 24 ¾” to the bottom of the ring. This level was actually too high to allow the ring to drop into my truck pintle hitch, so I will probably replace the jack or cut off the foot extension.

The surge brake also has a rotating lever in front of the master cylinder that may act as a break-away lever, as well as a parking brake. The system was dismantled on my trailer, so I could not verify this.

The trailer is constructed of 5” channel iron, 4” channel iron for the tongue jack mount, and 1 ½ x 2 ½ in angle iron for the 4 corner braces under the box. The trailer dimensions are overall length 169 5/8” (not including the step bolted on the rear) and frame width of 83 3/8”. The overall axle width wheel hub to wheel hub is about 100.5” The aluminum rear step is attached to the frame with 9/16" stainless steel bolts and nuts.

I’m not sure what’s the purpose of the tall steel structure at the front of the tongue, but the top plate has 4 bolt holes, and may be a braced mounting point for an antenna mast.

SHELTER

The shelter is attached to the trailer at 4 reinforced mounting points using a clevis-head bolt.

The shelter dimensions are:

Outside box (not including the tiedown brackets)

Width 80 5/16”

Length 100 1/16”

Height 77 9/16”

Outside box (including the tiedown brackets) w/o clevis bolts & pins

Width 81 ¼”

Length 109 1/8”

Height 79”

Outside box (including the tiedown brackets) with clevis bolts & pins

Width 83" (other dimensions same)

Inside Box

Width ~75 ¾”

Length 96 3/16”

Height ~73 ½”

The wall thickness seems to be about 2”, constructed of aluminum frame and sheet. The only steel found on the shelter are the corner lift/tie down brackets and rings, some of the door hardware, roof access steps. Don’t know if the insulation is solid foam or fiberglass matt, or ?.

The floor is asphalt tile, with a floor drain with plug just to the right of the door.

The air conditioner is a Friedrich UE08D11C 8000 BTU Uni-Fit Series Room Air Conditioner with Electric Heat, 115 volts, and the freon has been removed from all the units I inspected (removal certification notice in some of the shelters). The AC is still available for about $630 from Amazon as of May 2019.

There are two vents to either side of the AC, and the shelters had none or one or two tubeaxial fans installed. The one in mine is labled NSN 4140-00-018-6535, made by Rotron, and dated 5-17-84.

Different shelters came with electronic racks or cabinets, but all seemed to come with a communication wiring array mounted to the passenger side of rear wall, with a cable to the wiring connector pass-through mount on the passenger side wall (supposed to have an inside cover but mine was missing). A lift-up door on the outside provides access to the wire connection points. The top hinge on this outside door on my shelter was frozen, and the pop rivits were broken, so when I removed the 4 bolts securing the door, it fell off. I’ve seen at least 3 variations of the wiring panel on the passenger wall.

Power to the shelter enters through the access port commonly found on other shelters (3 variations have been seen). Connections on mine are 4-wire female threaded plugs. On the other side of this port on the driver side rear wall is a breaker panel (I’ve seen 2 types of panels). Power supply is 120 volt, 30 amp, single phase. Lighting is 3 fluorescent light fixtures along the front and side walls. Empty fiberoptic cable raceways also travel along the ceiling.

The four corners of the roof are steel/iron with swiveling lift/tie down rings. Most, if not all of the shelters had 2 cables permanently mounted to the rings and interwoven loops formed at the middle for lifting. My shelter roof had a square patch sheet of aluminum in the middle, but there is no indication of roof access inside the shelter. This may be protection from lifting hooks or attachments hitting the roof during shelter lifts.

Another penetration on the upper front driver side wall is a 90 degree copper or brass hollow elbow, which is closed on the outside. Two holes marked V (verticle?) and H (horizontal?) are directly below the elbow. These will have to be plugged as they will let in rain.

More to come as I learn more....

Last edited: