cowboy3500

New member

- 1

- 0

- 1

- Location

- Dyke, VA

Hello,

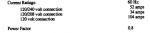

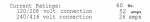

I have the MEP803 generator to run a 10 HP three phase motor. I am trying to figure out whether that generator will run my 10 HP 20-230/460 Cardboard baler. The description on an MEP803 says 120/208 volts, so I'm assuming it won't work because of the low voltage rating but for the MEP804 it says 120/208, 240/416 Volts 3 Phase. I don't have a deep understanding of three phase but would the MEP804 run my 3 phase motor? The motor tag is attached.

Thanks,

I have the MEP803 generator to run a 10 HP three phase motor. I am trying to figure out whether that generator will run my 10 HP 20-230/460 Cardboard baler. The description on an MEP803 says 120/208 volts, so I'm assuming it won't work because of the low voltage rating but for the MEP804 it says 120/208, 240/416 Volts 3 Phase. I don't have a deep understanding of three phase but would the MEP804 run my 3 phase motor? The motor tag is attached.

Thanks,

Attachments

-

58.2 KB Views: 14