-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

FDC bypassed and crankcase still floods with fuel

- Thread starter crazywelder72

- Start date

More options

Who Replied?DieselBob

Active member

- 2,891

- 15

- 38

- Location

- Arnold Maryland

Nice find. Thanks for posting the movie..![Thumbs Up [thumbzup] [thumbzup]](https://www.steelsoldiers.com/images/smilies/icon_smile_thumzup.gif)

crazywelder72

New member

- 701

- 2

- 0

- Location

- Winchester Ma

Actuator O-Ring: .426 x .070 = -013 or 013 (depending on which standard)

Out of curiosity, how much liquid did you pull out of your oilpan when you drained it? I was diluted ~3:1 with diesel, and have found some bearing damage on my mains.

Thats about how much mine was. I got about 15 gallons +/- a gallon or so.

How long was yours leaking before you noticed the damage? what did you do about it? what do you do to look for bearing damage? drop the pan and.....?

That's almost exactly how much I pulled out of mine. You can imagine the mess when my 5ga oil pan wasnt really up to the job  .

.

When I drained the fluid I found some suspect metal shavings, pulling the oil filters and cutting them open confirmed I had an issue. I did finally drop the pan and start pulling the mains. Some of them are fine, some need to be replaced. Fortunately no crank damage encountered yet. I don't know how long it was running like that, I'm guessing 100-200 miles.

Here are the related threads, if I would have realized they were the same issue I would have kept it to one and had a different title:

http://www.steelsoldiers.com/deuce/85779-fix-leaky-fdc.html

http://www.steelsoldiers.com/deuce/86101-found-these-oilpan.html

When I drained the fluid I found some suspect metal shavings, pulling the oil filters and cutting them open confirmed I had an issue. I did finally drop the pan and start pulling the mains. Some of them are fine, some need to be replaced. Fortunately no crank damage encountered yet. I don't know how long it was running like that, I'm guessing 100-200 miles.

Here are the related threads, if I would have realized they were the same issue I would have kept it to one and had a different title:

http://www.steelsoldiers.com/deuce/85779-fix-leaky-fdc.html

http://www.steelsoldiers.com/deuce/86101-found-these-oilpan.html

crazywelder72

New member

- 701

- 2

- 0

- Location

- Winchester Ma

I have read the "fix for a leaky fdc" but not the other one. I was lucky that a member told me to have a few 5 gallon buckets around. I thought he was exaggerating. I havent noticed anything in the oil. But i haven't looked to hard either.

Now I am trying to find out how to or what to tear apart to get at that o ring on the shaft. Let me guess,,,,, the HH has to come out?

Now I am trying to find out how to or what to tear apart to get at that o ring on the shaft. Let me guess,,,,, the HH has to come out?

You could potentially do it w/o removing the HH. The tough part is going to be the small needle in the HH that goes into the end of the actuator shaft.

Unbolt the bracket (where the safety wire is) and pull straight out. The o-ring is on the shaft that slides out of the head.

If the pin falls out you may need to pull the HH to fish it out. I recommend aligning the marked tooth on the HH to the arrow on the IP body before hand just in case. Not sure if it's even possible for the pin to fall down inside, but just in case.

Unbolt the bracket (where the safety wire is) and pull straight out. The o-ring is on the shaft that slides out of the head.

If the pin falls out you may need to pull the HH to fish it out. I recommend aligning the marked tooth on the HH to the arrow on the IP body before hand just in case. Not sure if it's even possible for the pin to fall down inside, but just in case.

I did also and it still leaked.I bought a new one from White Owl; problem fixed.

crazywelder72

New member

- 701

- 2

- 0

- Location

- Winchester Ma

I pulled that shaft when i was doing the HH obviously the first time. I had no problem removing it without loosing the tiny key.You could potentially do it w/o removing the HH. The tough part is going to be the small needle in the HH that goes into the end of the actuator shaft.

Unbolt the bracket (where the safety wire is) and pull straight out. The o-ring is on the shaft that slides out of the head.

If the pin falls out you may need to pull the HH to fish it out. I recommend aligning the marked tooth on the HH to the arrow on the IP body before hand just in case. Not sure if it's even possible for the pin to fall down inside, but just in case.

Curious - what happens when the engine runs with the in-tank pump off? Does this change the area around the leaky o-ring from pressure (in-tank pump running) to suction (IP is drawing fuel out of the tank), in which case fuel would not dilute the oil? If this conjecture is correct, then this might be a field expedient means of driving home without killing your bearings.

DieselBob

Active member

- 2,891

- 15

- 38

- Location

- Arnold Maryland

I would tend to think it will leak even more with the engine running. The in-tank pump only has around 7 ~ 8 PSI but with the engine running the mechanical fuel pump will go up to 60 PSI.

But is the mechanical pump before or after the leak? If after, the leaky oring will see suction instead of that 60 psi.I would tend to think it will leak even more with the engine running. The in-tank pump only has around 7 ~ 8 PSI but with the engine running the mechanical fuel pump will go up to 60 PSI.

DieselBob

Active member

- 2,891

- 15

- 38

- Location

- Arnold Maryland

The mechanical pump is before the leak. The in-tank pump pushes fuel from the tank through the primary filter to the mechanical pump. The mechanical pump then pushes fuel through the secondary and final fuel filters and into the HH.But is the mechanical pump before or after the leak? If after, the leaky oring will see suction instead of that 60 psi.

Thank you. Now I see how you can end up with gallons of fuel in your crankcase. The little seep seen in the video with just the in-tank pump running must be like a bathtub faucet with 60 psi behind it.The mechanical pump is before the leak. The in-tank pump pushes fuel from the tank through the primary filter to the mechanical pump. The mechanical pump then pushes fuel through the secondary and final fuel filters and into the HH.

crazywelder72

New member

- 701

- 2

- 0

- Location

- Winchester Ma

I could take another video?????  But I would be afraid of getting my camera sprayed with fuel. Besides..... that would be real messy.

But I would be afraid of getting my camera sprayed with fuel. Besides..... that would be real messy.

I just don't remember seeing a oring on that shaft. Now i need to look thru my pics and see what i can find.

But I would be afraid of getting my camera sprayed with fuel. Besides..... that would be real messy.

But I would be afraid of getting my camera sprayed with fuel. Besides..... that would be real messy.I just don't remember seeing a oring on that shaft. Now i need to look thru my pics and see what i can find.

crazywelder72

New member

- 701

- 2

- 0

- Location

- Winchester Ma

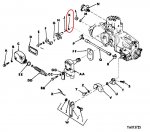

This is a pic i found from a different thread. Where on here is the O-ring supposed to go?

Attachments

-

19.7 KB Views: 42

-

19.7 KB Views: 46

DieselBob

Active member

- 2,891

- 15

- 38

- Location

- Arnold Maryland

From the description and diagram it should have been on the shaft or in the bore the shaft slides into.

"b. Refer to figure 3-149. Install fuel control unit

assembly with new preformed packing, so that plunger

sleeve pin (A, fig. 3-47) engages plunger sleeve slot (fig.

3-14 . "

. "

"b. Refer to figure 3-149. Install fuel control unit

assembly with new preformed packing, so that plunger

sleeve pin (A, fig. 3-47) engages plunger sleeve slot (fig.

3-14

Attachments

-

61.2 KB Views: 47

davey8943

Member

- 334

- 2

- 18

- Location

- Columbus IN

The o-ring goes behind that diamond shaped piece of flat steel.

I added an arrow to your picture to show it.

If you need one, I would be happy to drop one in the mail (I bought ~30 of them when I needed just the one to fix the same problem with my m35) Just pm me your address and it'll be on the way....

Dave

** Edit -- I was going to add a shot of the TM, but it looks like DieselBob is just a bit quicker than me

I added an arrow to your picture to show it.

If you need one, I would be happy to drop one in the mail (I bought ~30 of them when I needed just the one to fix the same problem with my m35) Just pm me your address and it'll be on the way....

Dave

** Edit -- I was going to add a shot of the TM, but it looks like DieselBob is just a bit quicker than me

Attachments

-

20.4 KB Views: 34

Last edited:

DieselBob

Active member

- 2,891

- 15

- 38

- Location

- Arnold Maryland

Found it...Backs up to the mounting plate..

Attachments

-

27.6 KB Views: 29

crazywelder72

New member

- 701

- 2

- 0

- Location

- Winchester Ma

Thanks guys...

davey8943

Member

- 334

- 2

- 18

- Location

- Columbus IN

- 114,396members

- 167,273threads

- 2,354,814posts

- 4,302online users