DownRange762

New member

- 37

- 0

- 0

- Location

- Zachary, LA

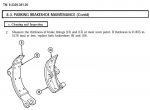

Can someone direct me to the TM and Work Package reference for the proper adjustment of the A3 parking brake? I get the concept that many just crank down on the adjustment by the parking brake drum until it feels good, but I'm looking for some actual reference measurements and diagrams. I've toured 24-1-1 and either missed it or it is in another TM that I haven't gotten to yet.

Also, it is correct that on a slope with the engine off the truck will roll regardless of it being in any of the Drive or Reverse gear, right? The day I took possession of my A3 I had to back it up the ramp into my shop (with the mirrors folded in to clear the door opening) and it would have been nice to stop the truck occasionally with or without the engine running to confirm I wasn't about to hit anything.

My parking brake, even with the in-cab adjusting knob fully turned, won't even come close to holding this truck on a slight slope, let alone pass the test of holding the truck in Drive.

Also, it is correct that on a slope with the engine off the truck will roll regardless of it being in any of the Drive or Reverse gear, right? The day I took possession of my A3 I had to back it up the ramp into my shop (with the mirrors folded in to clear the door opening) and it would have been nice to stop the truck occasionally with or without the engine running to confirm I wasn't about to hit anything.

My parking brake, even with the in-cab adjusting knob fully turned, won't even come close to holding this truck on a slight slope, let alone pass the test of holding the truck in Drive.