- 2,054

- 59

- 48

- Location

- Milford / Michigan

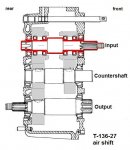

I backed out of my parking spot yesterday at work and heard what seemed to be a gear grinding. A gear grinding a little like how something would sound if not engaged all the way. It did not in any way effect how the truck backed up, nothing shuttered at all and no loud crunching. I got scared and thought maybe the transfer case lever got bumped down or something. I looked and saw it was down a little bit lower, so I pulled it up and it went into its detent for the high range position. The lever some how got lowered (probably lowered itself when the bearing gave loose). When I drove it up the road after that, I could hear a bearing whining in the transfer case area. I at least knew I had a bad bearing somewhere. To troubleshoot what it could be, I put the transfer case in neutral, put the transmission in 4th gear and engine running. I climbed under the truck to listen. I could hear the noise coming from the transfer case. It sounded like a very light bearing noise mixed with a little gear clanking sound. Next I shut the truck off and removed the jack shaft. I did the same test with the engine running, transmission in 4th gear and transmission only spinning. There was no sound at all. I knew it was in the transfer case. I then spun the transfer case by hand with the transfer in neutral. I could feel a very slight binding once in a while spinning it by hand. I could also hear the sounds of what seems like a ball bearing without the bearing cage and the balls spinning on the race and then a “dropping” sound like they went over center in the bearing races and then fell down to the bottom of the race. This would make sense because when I changed my transfer case oil when I bought the truck 2 and a half years ago (15,000 miles since I bought it), I found pieces of a bearing cage then. So if sound I heard sounds like a ball bearing without the cage, I would think my diagnosis is pretty close. I also found the input shaft of the transfer case moved in and out about .020.

Now the part that could be my fault is I had a leaky input seal and the oil was exactly a quart low. I topped it off about 2 weeks ago, but it must have leaked out by then. I ordered the seal from Napa a couple days ago too. Either way, the lack of a quart of oil could have been a part in the bearing going. Then again, when I bought the truck, I found a piece of bearing cage… so who knows.

Last night I got everything disconnected from the transfer case and the only thing holding it in is the mounts. Tonight Dad and I are going to pull it out and start the process of taking it apart to see what happened.

One thing I have always noticed with the truck since I got it is that under power, the transfer case lever drops a very little bit and when I coast down a hill and let the engine hold me back, the transfer case lever comes up a little bit. Is this at all connected to the fact that there was maybe .020” play the input shaft of the transfer case had when I pulled it in and out? I am just wondering if it is at all connected to each other somehow or if it is just the case flexing in the rubber mounts.

So if I am doing a tear down, inspection and repair of the transfer case, is there anything special I should look at? What else are the transfer cases prone to wear and breaking? What else would you guys do to this transfer case if you had one apart to replace a bearing?

Attached are pictures of what i found when i drained the oil.

Now the part that could be my fault is I had a leaky input seal and the oil was exactly a quart low. I topped it off about 2 weeks ago, but it must have leaked out by then. I ordered the seal from Napa a couple days ago too. Either way, the lack of a quart of oil could have been a part in the bearing going. Then again, when I bought the truck, I found a piece of bearing cage… so who knows.

Last night I got everything disconnected from the transfer case and the only thing holding it in is the mounts. Tonight Dad and I are going to pull it out and start the process of taking it apart to see what happened.

One thing I have always noticed with the truck since I got it is that under power, the transfer case lever drops a very little bit and when I coast down a hill and let the engine hold me back, the transfer case lever comes up a little bit. Is this at all connected to the fact that there was maybe .020” play the input shaft of the transfer case had when I pulled it in and out? I am just wondering if it is at all connected to each other somehow or if it is just the case flexing in the rubber mounts.

So if I am doing a tear down, inspection and repair of the transfer case, is there anything special I should look at? What else are the transfer cases prone to wear and breaking? What else would you guys do to this transfer case if you had one apart to replace a bearing?

Attached are pictures of what i found when i drained the oil.

Attachments

-

107.4 KB Views: 137

-

83.7 KB Views: 181

Last edited by a moderator: