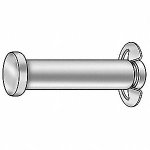

I replaced my hood hinges with new ones from Memphis just before SSGR13. The pin in the passenger side hinge fell out during the rally. Fortunately my son noticed that the pin had come out and it was just lying on the hood, so I was able to grab it and put in the glove box. I put the pin back in, but the fit between the splines on the pin and the hole through the hinge is not tight enough so it won't stay in. I've been thinking about getting the hinge over to a fab shop to see if they can press it in, weld it, or may be press it in and deform the skinny end so it can't come out again.

How were you thinking of rebuilding the hinges? on my old ones, the through holes were elongated and the pins fit very loosely. That allowed a lot of movement at the hinge resulting in all manner of squeaks, rattles, and rubbing that removed the paint and ended up making rust. I'm not sure how those old hinges could have been fixed short of filling the holes, re-drilling them and then fitting new pins.