m35a2cowner

Member

- 369

- 2

- 16

- Location

- Columbus, Ohio

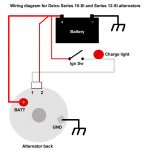

Sorry if this is a little bit off topic, but has anyone thought of mounting a 12 volt alternator under the cab to be driven off of the intermediate drive shaft between the transmission and the transfer case. It would charge while the truck is moving and if you needed power and no movement you could put the transmission in gear and the transfer case in neutral and turn the alternator. More room, less vibration, less in the way when doing maintenance. They make self exciting kits for delco alternators, one wire to the battery. I have one on my rail-car (20 HP Wisconsin motor) and it works like a champ. I got it from a small shop that repairs alternators and starters. I have seen one of these self exciting alternators attached to an old chain saw bar and used as a portable battery charger. Just a thought from outside the toolbox.