wreckerman893

Possum Connoisseur

- 15,647

- 2,141

- 113

- Location

- Akenback acres near Gadsden, AL

Sounds like the Boss Lady knows how to take care of her man. She's a keeper.My wife had a custom 12 volt accessory kit made for me as a Christmas gift.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Sounds like the Boss Lady knows how to take care of her man. She's a keeper.My wife had a custom 12 volt accessory kit made for me as a Christmas gift.

swbradley1 - Thanks for the feedback! I read about the "magic smoke" in a number of threads when researching this project. It sounds like something I don't want to experience!You will want a 15 or 20A fuse on the input side of converter inline and as close to the battery where you acquire your 24VDC feed. Then a 30A on the output as close to the converter as possible.

This minimizes the change of a short to ground in the wiring releasing magic smoke.

Good looking setup.

Yes sir! She is definitely a keeper! Not only did she start this project by giving me the accessory kit, but she wasn't too terribly upset when I got home last night at 2100 instead of 1700 as anticipated.Sounds like the Boss Lady knows how to take care of her man. She's a keeper.

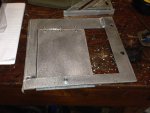

That is a TERRIFIC IDEA. A GREAT use of otherwise wasted space.So why go to a fabrication shop for the install? When planning this project, I drew the wiring diagram and purchased all of the components. The next obstacle was figuring-out where in the truck to mount the components. There was no obvious location. That's when it hit me, why not make a "shelf" between the dash and the fire wall to hold everything. The accessory kit mounts to the lip on the bottom of the dash. The front of the shelf sits in between the accessory kit and the lip on the dash, and the back of the shelf bolts to the fire wall. Lastly, I figured it would be handy if the Pyle converter mounted on a hinged door for easy access in the future.

I have a little touch-up painting to do, but otherwise this project is done.

Been there, done that! Although it was a fuel leak and not an electrical issue that caused the fire, it still WRECKED my day! I had just purchased a 1979 Chevy 4x4 and was driving it home when it burst into flames!A car fire can just WRECK your whole dang day.

Good suggestion, thanks! The top of the solenoid is rather close to the map box, but I bet there is room to turn the wires 180 degrees. I will have to check it out this weekend.If I could offer a small suggestion ... do you have enough room to turn the wires going to the solenoid 180 degrees, so that they come DOWN to the connection instead of going UP to the connection? It might prevent they getting snagged one day and tidy things up even a little more.

That's good to know! Thanks!On the last PNW rally it was running the CB, 2 phones an MP3 player and a GPS and didn't get warm.

Actually the whole inside of the truck can get really wet ! Up here in the NW with all the humidity my truck "rains on me" when I get inside ! I have found severe rust underneath the dash and really went after it this last summer. I also found the "hood" catch was leaking water bad ! I removed the bolt and screw and resealed both with a high quality Permatex RTV sealant. So far no leaks but the moisture inside the truck is ridiculous ! I have to bring a big towel out with me to wipe down the ceiling and sides of the cab when I want to start it up and go anywhere. I think I might put a small heater inside to keep the moisture at bay !Water on 12 volt items won't likely cause a short unless there is other material there that's likely to be a conductor. Think of the batteries and the wires that are running to them. They're out in the weather. You DO have to worry about corrosion on the copper and other metal bits inside electronics but under the dash is pretty dry.

While this is true, when you get water on a powered circuit with components like capacitors, transistors, resistors, etc, it does in fact cause component failures almost every time.Water on 12 volt items won't likely cause a short unless there is other material there that's likely to be a conductor. Think of the batteries and the wires that are running to them. They're out in the weather. You DO have to worry about corrosion on the copper and other metal bits inside electronics but under the dash is pretty dry.