- 1,673

- 898

- 113

- Location

- Central NY

Further to these threads:

http://www.steelsoldiers.com/showthread.php?127106-M916A1-Little-Stuff

http://www.steelsoldiers.com/showthread.php?123032-M916A1-w-w

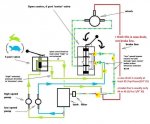

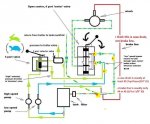

I wanted to fully understand the schematics of the PTO hyd/winch system with the plan to add the A3 wetline kit for trailer hydraulics.

It appears that the direction valve is a spool type - 'motor' or open center and the speed valve adds high speed to the low speed rather than changing to high speed. This is done by simply doubling the volume - a both pumps are 20 Gpm (DS Edit - post #13)

I am not totally aufait with hydraulics - so I stand corrected. PLEASE CORRECT IF APPROPRIATE!

Plan is to add 't's to the low speed circuit, then running just two lines to the bulkhead below the winch - see A3 pic.

John's added front winch would have had to have an additional motor valve with four lines similar to the existing direction valve (P T A B - pump, tank and two reversible flow lines to the winch motor).

NB - 916 (std system), A1/A2 electric idle control, A3 added wetline.

http://www.steelsoldiers.com/showthread.php?127106-M916A1-Little-Stuff

http://www.steelsoldiers.com/showthread.php?123032-M916A1-w-w

I wanted to fully understand the schematics of the PTO hyd/winch system with the plan to add the A3 wetline kit for trailer hydraulics.

It appears that the direction valve is a spool type - 'motor' or open center and the speed valve adds high speed to the low speed rather than changing to high speed. This is done by simply doubling the volume - a both pumps are 20 Gpm (DS Edit - post #13)

I am not totally aufait with hydraulics - so I stand corrected. PLEASE CORRECT IF APPROPRIATE!

Plan is to add 't's to the low speed circuit, then running just two lines to the bulkhead below the winch - see A3 pic.

John's added front winch would have had to have an additional motor valve with four lines similar to the existing direction valve (P T A B - pump, tank and two reversible flow lines to the winch motor).

NB - 916 (std system), A1/A2 electric idle control, A3 added wetline.

Attachments

-

76.3 KB Views: 114

-

61.5 KB Views: 129

-

63.6 KB Views: 111

Last edited: