StoneyHill

Member

- 38

- 0

- 6

- Location

- Florence SC

I got a M1009 from Ft. Meade. Was not running. Replaced the batteries and a blown 20amp Engine Control Fuse. The truck then started and ran. I ran it a bit and then tried to start it later and the 20amp Engine Control fuse was blown again.

When the fuse is blown, the wait light will not come on and the truck will not start if cold.

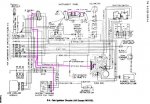

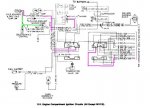

I am trying to troubleshoot what could be blowing the fuse. I would love to find a diagram of what is in the Engine Control 20amp circuit. I have done a few searches and found the diagrams in the -20 TM. They are clear as mud.

I do not see the Engine Control fuse or circiut mentioned. Is there another place I need to look for a diagram of that circuit?

Has anyone else had problems with this fuse blowing? What was your solution.

Thanks for any help guys.

SCott

When the fuse is blown, the wait light will not come on and the truck will not start if cold.

I am trying to troubleshoot what could be blowing the fuse. I would love to find a diagram of what is in the Engine Control 20amp circuit. I have done a few searches and found the diagrams in the -20 TM. They are clear as mud.

I do not see the Engine Control fuse or circiut mentioned. Is there another place I need to look for a diagram of that circuit?

Has anyone else had problems with this fuse blowing? What was your solution.

Thanks for any help guys.

SCott