cpotato2001

New member

- 24

- 0

- 1

- Location

- Papillion, Nebraska

That's the result of a 50hr work week and 3 nights of school,been three daze

not heard a thing here

Sent from my iPhone using Tapatalk

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

That's the result of a 50hr work week and 3 nights of school,been three daze

not heard a thing here

That's the result of a 50hr work week and 3 nights of school,

Sent from my iPhone using Tapatalk

I would be a lot happier if I had time to work on things that make me happy. I am hoping things slow down a little bit soon. I will get to it soon! ; )I forgot what I taught myself

The only difference between working and being retired is that now I decide when I will be tired and what I will do next.

Worked for 49 years and be done now and did forget really fast about schools and work weeks.

my bad

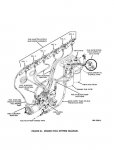

Search for threads on turning up the fuel, usually done one or two 'flats' at a time. A pyrometer is usually recommended between the exhaust and the turbo as the first step (too much fuel= hotter exhaust temps, esp under load) because the pistons will start melting at 1200 degrees F. Have you 'pop tested' your injectors (I can't remember if you said you did). There are several threads about doing that and getting them all up to snuff before starting on the fuel delivery increase.How do I turn up the fuel if I decide to just go rogue and see what happens?

Checked fuel pressure today at the bleed on top of the fuel filters.

7 PSI from the lift pump with engine stopped.

49 PSI with engine running at idle.

Is this good?

Please note which pump model was replaced with which pump model.A couple years ago the truck stopped running - from what appeared to be a snapped quill shaft in the Injection Pump. Over the course of a confused year or so I bought a NOS injection pump and gave it my best to install it. Well, my best wasn't good enough. Truck was extremely hard to start, made gutless power and died on deceleration most of the time. SO, it sucks and I let it sit.

I am going to try again to fix it and the only thing I can think of is I got the injection pump timed incorrectly. I am pretty sure it was at TDC (but I suck at this so who knows) and I timed it to the mark on the harmonic pulley for an LDT 465 1C (I think). I am also pretty sure I had the IP mark lined up correctly AND the quill shaft timed (I think).

Ive had months and months and months to think about why my truck sucks and it occurred to me that my truck shows to be an LDT 465 1D on the engine plate. Will it use a different mark?

FSM TM9 2815-210-34-2-2 Page 5-172 Doesn't show a mark to use for an LDT 465 1D - so I guessed.

If your "Fuel Density Compensator" was bypassed then it would not matter at all if the adjustment screw was out of adjustment. The sticky "operating rod" would cause all the problems though.Solved.

I hate reading through trouble threads and never finding out what the solution was.

In my case, the sluggishness was caused by a slightly sticky fuel rod AND mostly I think that the fuel screw adjustment was out of whack on the bypassed FDC.

I swapped my old FDC on (which had old settings) and played with the fuel rod until it moved freely.

I hope this helps someone else out so they don't go through the same frustration I did.