Update 1/5/18

It's been quite a while since my last update and much has progressed on the M152 project. The design changes on-the-fly as opportunities present themselves.

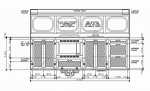

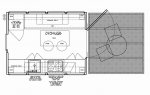

Currently, the large expedition rack is back from the finish welder and powder coat ready. I can tack weld, but horrible finish welder. Let someone else do it correctly. The rack has expanded metal side panels that exactly match the existing expanded metal window grids - so looks factory and includes 4 flag holders. After powder coat, will install the decking, 8 LED Zombie work lights and my Union Pacific Nathan K3LA three trumpet train horn before hoisting into place. It's heavy. Viar air compressor and 1.5 gallon tank are in the storage area under the dirver's seat with horn quilling valve readily on the right. These are insanely loud and sound ... well ... like a friggin' train? Thankfully, the stock horn is retained for the steering wheel.

The rear suspension will have a few leafs removed to lower and soften the ride. Independantly adjustable air shocks will be added and used for ride height and to level the truck when camping.

The window grids are now operable instead of stock fixed which gives the interior much more light when lifted and locked in the open position - and can clean the glass after 63 years. Hinges were added to the top bolts and strong N50 magnets to the bottom bolts. Grids snap shut with authority.

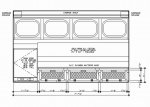

The bi-fold rear deck is almost ready for the finish welder. It holds a Pioneer tool rack, two Rotopax fuel packs and can hinge down and be a motorcycle ramp. The smaller portion unhooks, splits in half to get through the rear door and becomes an interior bunk bed when reassembled. Strong, full length, steel bunk bed cleats were added to the box sides using existing bolt locations and seriouly strengthened the box walls. If needed, in a Zombie epocolypse bug-out, the truck can comfortably carry 5 (two up front and 3 on the full size sofa) and sleep 3 inside and 2 outside on the rear deck or roof rack.

Body and paint: all bolt on items will be camo black such as fenders, bumpers, front grill, window grids, all lights, mirrors, roof rack, rear deck, power outlets, fuel inlet, etc. Main body, hood, doors, steps, etc will be olive drab or three color green camo. Have decided to spend money on soda blasting, rust mitigation, panel reconstruction and paint by others. As usual, there is a significant amout of rust at the roof gutter and some areas under the cab.

Still hunting for a Dana 60 front axle, 4.10 ratio, disc brakes, passenger drop. Hard to find.

Rear dually fenders: Getting ready to put the AAM rear dually axle under the M152. This extends the vehicle rear track about 7" per side for substantially more stability at highway speeds, but needs the addition of large rear fenders. Looking for WC-56 command car rear fenders that will be modified to fit or have custom fenders made. Want the fender lip detail to match the front fender insted of the rounded lip of M37 or WM300 rear fenders. The M152 box walls extend past the rear wheel tub a significant amout, so a larger fender opening can be carved into the box walls s to accomodate a larger diameter rear fender. Ths new fender can extend clear back to the existing tub side so the underneath looks continuously round and factory.

As a final note, it is hard to describe, but this build is becoming greater than the sum of its parts. Ultimately, I am very thankful for the opportunities made available by living in the United States. Dreams reinforced with hard work are truly rewarded. My design business was successful enough to allow me to retire early with good health, good friends and family. I count my blessings daily and now volunteer 3 days a week to a homeless kitchen. I think this is what Sea To Shining Sea is about. It's time to give back, time to pursue happiness, time to see the Nation, travel its backroads and meet its people ... and I cannot imagine a better way than in a very capable M152 tribute truck. We will travel all four corners and Alaska ... or bust.

The truck's logo for the 3 doors.

Happy New Year to all.

Glenn

Even grafting a M37 fender may not fit. May have to remove the interior tubs and repace it with matching M37 bed tubs. Will get it all figured out when the replacement 14 bolt axle is procured.

Even grafting a M37 fender may not fit. May have to remove the interior tubs and repace it with matching M37 bed tubs. Will get it all figured out when the replacement 14 bolt axle is procured.