-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

has anyone taken injectors apart on this forum?

- Thread starter 319cssb

- Start date

More options

Who Replied?Barrman

Well-known member

- 5,484

- 2,244

- 113

- Location

- Giddings, Texas

I took mine apart 8 years ago to try and refresh them. A pop tester is really needed after you take them apart to verify they are good. Buying new Bosch injectors is almost cheaper and easier in the long run.

I have one that leaks from the center section I think there is a copper gasket that seals the half But I am not sure.

I am 100% sure:

-the return lines are not leaking

-the fitting is not leaking

-the injector is not leaking from the bottom seal.

I had to write that, because someone will always inject a post with 'did you check the rubber return hoses'?

I am 100% sure:

-the return lines are not leaking

-the fitting is not leaking

-the injector is not leaking from the bottom seal.

I had to write that, because someone will always inject a post with 'did you check the rubber return hoses'?

Mg84648

Member

- 201

- 6

- 18

- Location

- Cumming, Ga

Did you check the rubber return hoses?I have one that leaks from the center section I think there is a copper gasket that seals the half But I am not sure.

I am 100% sure:

-the return lines are not leaking

-the fitting is not leaking

-the injector is not leaking from the bottom seal.

I had to write that, because someone will always inject a post with 'did you check the rubber return hoses'?

- 7,032

- 2,691

- 113

- Location

- Montevideo/Uruguay

Keith_J

Well-known member

- 3,657

- 1,328

- 113

- Location

- Schertz TX

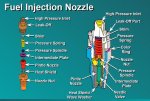

The fit of the top and bottom halfs (very hard steel) and the softer intermediate plate form the seal. The body seal is low pressure, fuel return. The intermediate plate seals the high pressure injection pressure (7000 PSI).

If the return lines are blocked, the body seal will see much higher pressure. When the injector "fires", the movement of the needle displaces fuel in the body, forcing it back to the tank. The actual weeping past the needle is tiny, just a few drops a minute.

If the return lines are blocked, the body seal will see much higher pressure. When the injector "fires", the movement of the needle displaces fuel in the body, forcing it back to the tank. The actual weeping past the needle is tiny, just a few drops a minute.

And I'll replace the return line tubing. I like the Idea of having them see through. I think everyone is raving about Tygon tubing. Is there a certain diameter size everyone uses?

Edit: I will get Viton tubing 5/16" 5 or 10ft of it

Edit: I will get Viton tubing 5/16" 5 or 10ft of it

Last edited:

Monkeyboyarmy

Well-known member

- 1,337

- 195

- 63

- Location

- Kingsville,Oh.

I don't think it's 5/16. Maybe 5/32??

id:1/8" od:5/16"i don't think it's 5/16. Maybe 5/32??

Monkeyboyarmy

Well-known member

- 1,337

- 195

- 63

- Location

- Kingsville,Oh.

Gotcha. That makes sense.

- 7,032

- 2,691

- 113

- Location

- Montevideo/Uruguay

There is tension, but only for the last couple threads before it gets tight, while assembling.

So no, nothing will fly apart...

To disassemble, put the injector upside down in a vise (protected with aluminum jaws!) and clamp very firmly(!) Then use your 30mm deep socket to crack it open. Be extremely careful when applying torque, because if the clamped flats slip- or begin to turn it may distort the small fuel return ports.

Only loosen both halves, then remove from vise and disassemble over a clean table or tray.

So no, nothing will fly apart...

To disassemble, put the injector upside down in a vise (protected with aluminum jaws!) and clamp very firmly(!) Then use your 30mm deep socket to crack it open. Be extremely careful when applying torque, because if the clamped flats slip- or begin to turn it may distort the small fuel return ports.

Only loosen both halves, then remove from vise and disassemble over a clean table or tray.

The first injector came out really clean. I used 99% alcohol and did three passes. first with the injector whole. second, with the injector cracked a bit ( so the parts could move inside) then I tool it apart and cleaned the lower portion again.

Then I cleaned with alcohol and kim wipes. Then I lubed the parts in diesel before assembly. I think I'll soak the injector in diesel before I put it back in the engine with a new copper gasket.

Not sure , yet about the soaking.

Then I'll put the injector back in the engine and if everything is ok in a week or so, I'll move on to the next injector.

Then I cleaned with alcohol and kim wipes. Then I lubed the parts in diesel before assembly. I think I'll soak the injector in diesel before I put it back in the engine with a new copper gasket.

Not sure , yet about the soaking.

Then I'll put the injector back in the engine and if everything is ok in a week or so, I'll move on to the next injector.

Last edited:

- 7,032

- 2,691

- 113

- Location

- Montevideo/Uruguay

50 ft.lbDo you know if there are any torque specs for tightening the halves back up later?

Is that not the torque value of how much the injector is supposed to be torqued to the engine block?50 ft.lb

or is the torque value of the injector halves the same?

- 114,373members

- 167,253threads

- 2,354,572posts

- 4,127online users