- 2,756

- 2,414

- 113

- Location

- Sunman Indiana

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

“A” is big at 1.288, compared to 1.225 of my stock accuride wheels.Compare yours with the dimensions shown below...

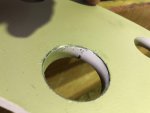

View attachment 761465

It seems to me that Ø "B" is within specs but Ø "A" is definitely too big...?

FWIW, "A" is 1.22" for the wheels on Deuces and M37s, and around 1.28" on HEMTT and FMTV wheels.

Since we are talking about stud-piloted steel wheels, even that little chamfer will be sufficient to center the adapter to the hub. But then when torquing down to 350 ft-lbs the nuts may start deforming that narrow seat, depending on how soft that steel is.

Just check your lug nuts frequently!

Not a problem.“A” is big at 1.288, compared to 1.225 of my stock accuride wheels. .......

Good; that means you (or a machinist) can still modify them for the correct chamfer. Not a big deal - if you have the right tool.“B” is small at 1.33, compared to 1.5 of my stock accuride wheels.

Happy feeling gone....

Happy feeling gone....Recheck your torque, ASAP, and if you get a chance, zip one of your nuts off and snap a picture for us.WCR is where I got mine from, I haven’t had a problem but I can’t remember if there was any chamfer.

...... and slight deformation in the nut. .................

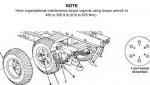

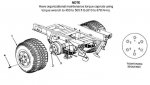

I think 450-500 is pretty standard.don't think id be comfy with that sharp edge or torquing the lugs to 500, i think the lugs are only supposed to be around 350 and the sharp edge may concentrate the force and deform lowering the torque, could lead to a cascade failure and launch a wheel after popping the studs...

Its also what the TM for my trailer calls for, single or dueled.

Its also what the TM for my trailer calls for, single or dueled.