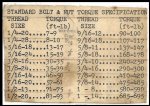

I posted this in another thread to answer a question if there are specific values that bolts are supposed to torqued too. The answer is yes, because what you are really doing from an engineering/physics standpoint is stretching the thread a predetermined amount. Not so important on various brackets and cab bolts, but all important when you're talking about engines, injector pumps, transmissions, seal housings, bearing housings, and suspension pieces. This chart has been taped to the inside of my toolbox lid for over 35 years. I hope my fellow soldiers will find it helpful. That's the spirit it was posted with.

I posted this in another thread to answer a question if there are specific values that bolts are supposed to torqued too. The answer is yes, because what you are really doing from an engineering/physics standpoint is stretching the thread a predetermined amount. Not so important on various brackets and cab bolts, but all important when you're talking about engines, injector pumps, transmissions, seal housings, bearing housings, and suspension pieces. This chart has been taped to the inside of my toolbox lid for over 35 years. I hope my fellow soldiers will find it helpful. That's the spirit it was posted with.-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Standard Bolt & Nut Torque Specifications

- Thread starter Dipstick

- Start date

More options

Who Replied?f3504x4

Member

- 48

- 15

- 8

- Location

- crescent city ca.

Awesome! Always have to look thru pages of tables to find a. Specific torque.View attachment 813079I posted this in another thread to answer a question if there are specific values that bolts are supposed to torqued too. The answer is yes, because what you are really doing from an engineering/physics standpoint is stretching the thread a predetermined amount. Not so important on various brackets and cab bolts, but all important when you're talking about engines, injector pumps, transmissions, seal housings, bearing housings, and suspension pieces. This chart has been taped to the inside of my toolbox lid for over 35 years. I hope my fellow soldiers will find it helpful. That's the spirit it was posted with.

Thank you! I'm glad you found it useful. Sometimes when I'm beat and my hands are stained with grease, I just want a quick, reliable answer. This chart has provided that for me. I am aware that their are certain situations in which specific manufacturer requirements may differ a bit from the chart. I'm thinking potentially about connecting rods or main bearing caps. Bearing housings with end caps that are meant to put a slight crush on the outer race of a ball bearing to prevent it from spinning are another. An example of that would be some horizontal split-case centrifugal pumps or transmissions. Still, the majority of the time this chart provides for sound mechanical practice. May all of your repairs be successful!

- 6,425

- 4,990

- 113

- Location

- Ft. Lauderdale, Florida

Torque means more about horsepower than horsepower does.

Attachments

-

71.3 KB Views: 11

-

315.8 KB Views: 9

Wow Frank that those are some interesting specs! Realistically, I think carbon steel hex head Grade 5 ( 3 raised Marks ) and Grade 8 ( five raised marks ) bolts are the most common bolts a Steel Soldier will likely see. I think this also applies to nuts installed over studs as well. The thread count and pitch for a given diameter is the thing. My engineer Dad told me as a young kid, that torque as it applies to engines, can be thought of as providing acceleration and load pulling ability, while horsepower more closely relates to sustained or top speed once torque has gotten the load or vehicle moving. Two great examples of this are railroad locomotives and drag racing cars. Horse power is an easy method for rating an engines power for the purpose of comparison, but it's really torque that gets it done. I got a little off the subject matter here. Sorry.

f3504x4

Member

- 48

- 15

- 8

- Location

- crescent city ca.

Your a weslth of knowledge! Thank youTorque means more about horsepower than horsepower does.

- 8,698

- 3,204

- 113

- Location

- Monrovia, Ca.

Both of those are awesome, Here is a PDF of the stuff I copied out of a manual and took to a friends house that the original Dirt Bag crew works on out junk of.

Attachments

-

4.8 MB Views: 9

Thank you Will! Just glanced over them and the top of my head exploded! I'm going to have to look at it again when I've had more rest. The metric stuff just gives me brain freeze every time.Both of those are awesome, Here is a PDF of the stuff I copied out of a manual and took to a friends house that the original Dirt Bag crew works on out junk of.

f3504x4

Member

- 48

- 15

- 8

- Location

- crescent city ca.

Great info sir! When i need the info wich is not often i can never find the conversion tables to save my fanny! Ty againBoth of those are awesome, Here is a PDF of the stuff I copied out of a manual and took to a friends house that the original Dirt Bag crew works on out junk of.

- 8,230

- 20,787

- 113

- Location

- Charlotte NC

Dipstick,View attachment 813079I posted this in another thread to answer a question if there are specific values that bolts are supposed to torqued too. The answer is yes, because what you are really doing from an engineering/physics standpoint is stretching the thread a predetermined amount. Not so important on various brackets and cab bolts, but all important when you're talking about engines, injector pumps, transmissions, seal housings, bearing housings, and suspension pieces. This chart has been taped to the inside of my toolbox lid for over 35 years. I hope my fellow soldiers will find it helpful. That's the spirit it was posted with.

That is an outstanding chart. A big number of the bolts on these MVs will be Grade 5 and the other values for Grade 8 were offered up by frank8003 so we have everything we need.

Yes Sir! Handy "cheat notes" are a wonderful thing. Especially when you are tired from a day of hustling up and down the side of the truck!

Thanks Owen! Nice contribution!

- 8,698

- 3,204

- 113

- Location

- Monrovia, Ca.

Print them, can't tell you how many times these have helped out. Beware though, SOME manufacturers have separate, other than these standard torques. Something that comes to mind is New Flyer busses. They USED to ship us busses with the axles removed. We....Cummins....would torque them to the "general" torque specs in our manuals. Well, turns out they weren't adequate. A component failed after a repair, they, the bus mfgr and the transit outlet, went after Cummins for the failed parts/pieces. We told them we always returned their vehicles with the part torqued to the generic spec. Turns out, the BUS OWNER was at fault because the mfgr stated that the fasteners removed were a 1 time use only. Just a word of caution

- 8,230

- 20,787

- 113

- Location

- Charlotte NC

Pretty amazing Will...Print them, can't tell you how many times these have helped out. Beware though, SOME manufacturers have separate, other than these standard torques. Something that comes to mind is New Flyer busses. They USED to ship us busses with the axles removed. We....Cummins....would torque them to the "general" torque specs in our manuals. Well, turns out they weren't adequate. A component failed after a repair, they, the bus mfgr and the transit outlet, went after Cummins for the failed parts/pieces. We told them we always returned their vehicles with the part torqued to the generic spec. Turns out, the BUS OWNER was at fault because the mfgr stated that the fasteners removed were a 1 time use only. Just a word of caution

Who knows, maybe we were just lucky but the only thing that ever got a torque wrench applied to it 40 years ago when I was turning wrenches on big trucks was the engine, hogshead, transmission and transfer case.

It wasn't at all abnormal to use the impact gun (Ingersol 238 at the time) to crank down the bolts on axle shafts. You just learned how many "hits" it took to get it right. Never had that problem. Maybe it was just older and more forgiving equipment.

On the other hand, the Hi-Rangers and derricks had turntable bolts that were "one use and done" every time - no exceptions. Lives depended on it being done that way...

Yup. I can see some frame bolts and such being put on with an impact wrench. Many times professional truck mechanics are under a lot of pressure to get it done. I worry most about under torquing fasteners and having something come loose while operational and I hate the idea of stripping out threads in say a cylinder head due to over-tightening. That's when I pay really close attention to torque. I don't think I've ever used one and done bolts. I'm glad I started this thread. I greatly appreciate all of the knowledge and information that each of you shared with me and the others.

- 8,230

- 20,787

- 113

- Location

- Charlotte NC

Yup. I can see some frame bolts and such being put on with an impact wrench. Many times professional truck mechanics are under a lot of pressure to get it done. I worry most about under torquing fasteners and having something come loose while operational and I hate the idea of stripping out threads in say a cylinder head due to over-tightening. That's when I pay really close attention to torque. I don't think I've ever used one and done bolts. I'm glad I started this thread. I greatly appreciate all of the knowledge and information that each of you shared with me and the others.

Owen, You are definitely right! This thread is a really good exercise in reality and a first class "brain check" for everybody that works on trucks.

You can't really U N D E R S T A N D torque and how important it is - until you put on a tire, don't get it right - and the tire comes off (or loose) five miles from home. Or that universal joint that you just "snugged up" and forgot to go back and tighten it down - and the driveshaft falls out going down the road...

You have to see or do "stupid" at least once to understand how important it is to DO IT RIGHT.

AMEN Tim!!! I have seen and done stupid myself. Now, I really pay attention to what I'm doing. Especially when rotating assemblies are involved! By the way, I was visiting with an 87 year old former Navy Electricians Mate today. Mitch served from 53-57'. I'm 67 and served from 73-77'. Twenty years apart. We hit it off in one nanosecond!

- 18,177

- 27,305

- 113

- Location

- Burgkunstadt, Germany

I worked on turbine gen sets. Cost of engine, $255,000. EVERY bolt, nut and screw was supposed to be torqued IAW the TM.

I once saw a gen set destroy the engine, because someone under torqued, (Its close enough for government work!) a drive assembly, for the regenerator wheels. Cost of repair? $255,000.

I once saw a gen set destroy the engine, because someone under torqued, (Its close enough for government work!) a drive assembly, for the regenerator wheels. Cost of repair? $255,000.

- 6,425

- 4,990

- 113

- Location

- Ft. Lauderdale, Florida

some more...

Attachments

-

1 MB Views: 4

-

848.5 KB Views: 4

-

3.4 MB Views: 2

Now that's a scary thought! I'll have to ask my brothers about that. They're both mechanical engineers and design turbine engine parts. One works for Pratt & Whitney and the other for General Electric.I worked on turbine gen sets. Cost of engine, $255,000. EVERY bolt, nut and screw was supposed to be torqued IAW the TM.

I once saw a gen set destroy the engine, because someone under torqued, (Its close enough for government work!) a drive assembly, for the regenerator wheels. Cost of repair? $255,000.

Thanks Frank! I especially want to read screw thread design!some more...

- 18,177

- 27,305

- 113

- Location

- Burgkunstadt, Germany

The good thing about the D424A, 150 KW gen set was that the engine casing was cast iron. All the little widgets stayed inside. We had a 30 KW that had two yellow lines painted on it. Wasn't healthy to stand between the yellow lines.Now that's a scary thought! I'll have to ask my brothers about that. They're both mechanical engineers and design turbine engine parts. One works for Pratt & Whitney and the other for General Electric.

- 114,353members

- 167,221threads

- 2,354,187posts

- 2,241online users