sunny every day

New member

- 5

- 3

- 3

- Location

- Tampa Bay, Florida

Any Diesel techs in the Tampa/Saint Petersburg area ?

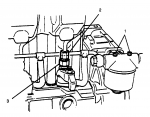

MEP-803 generator.

Cranks, but doesn't run.

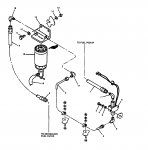

Fuel changed. Filter/water separator changed. Secondary fuel filter changed.

MEP-803 generator.

Cranks, but doesn't run.

Fuel changed. Filter/water separator changed. Secondary fuel filter changed.