- 519

- 1,122

- 93

- Location

- Germany

Not much progress

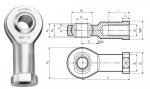

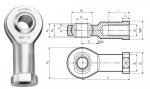

We start to customize the shiftlinkeage

But we need this special bolt (german: Gelenkkopfschraube) in metric as i have not the right thread cutting dies in inch

I ordered today as here is no shop which have such material on the shelf.

We use the TH400 linkeage as template

![20241019_124710[1].jpg 20241019_124710[1].jpg](https://www.steelsoldiers.com/data/attachments/689/689107-74afe77545437571f1c2a0c3d4551385.jpg)

At least the oiltemp sensor for the 4l80e made no problem by installation

we bring both wires - oiltemp transmission and oiltemp engine though this stock passage in the firewall near the steering column

and connect both on their own BIM-04-2 module in the glove box

Now need to find a shop which customize us oillines for the transmission cooler.

We need 2x 90 inches. Nothing seen what was ready to install.

We start to customize the shiftlinkeage

But we need this special bolt (german: Gelenkkopfschraube) in metric as i have not the right thread cutting dies in inch

I ordered today as here is no shop which have such material on the shelf.

We use the TH400 linkeage as template

![20241019_124710[1].jpg 20241019_124710[1].jpg](https://www.steelsoldiers.com/data/attachments/689/689107-74afe77545437571f1c2a0c3d4551385.jpg)

At least the oiltemp sensor for the 4l80e made no problem by installation

we bring both wires - oiltemp transmission and oiltemp engine though this stock passage in the firewall near the steering column

and connect both on their own BIM-04-2 module in the glove box

Now need to find a shop which customize us oillines for the transmission cooler.

We need 2x 90 inches. Nothing seen what was ready to install.