shawnspeak

New member

- 14

- 19

- 3

- Location

- Bend, Or

No instructions in the kit here

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

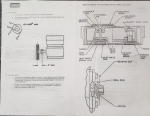

All of the Haldex RNT26 kits I have bought came with an instruction sheet.No instructions in the kit here

Hopefully you got an answer, but found this in the sealed white envelope with all the gasketsIf someone could take a picture of the sheet and post it here, both I and the next unfortunate soul without one would greatly appreciate it. Otherwise, fingers crossed for responses from Haldex and/or the vendor I bought the kit from.

Sorry for my ignorance. Where is this two way valve located? We have air coming out of our Red glad hand on the A1. TYI suspect you will still find leakage elsewhere. There is an output check valve on the air dryer, so once the air is pumped past that, there should be no going back to the compressor... If it is happening while driving, i would first inspect the park air lines, anti-compound valve and spring chambers. a park chamber leak would pass out thru the cage bolt holes. Depending on your year, you may also have a remote control valve inboard of the pri-sec tanks that disconnects air to the air/hydraulic pump when park air is applied.

Chock the wheels release the park brakes, a bad 2way could send park air out the front red glad-hand vent. Are the rear glad-hands capped/sealed? Fronts are vented, rears must be sealed...

There's three two way valves behind the driver's side step curtain. Look UP behind the step with the washer bottle.Sorry for my ignorance. Where is this two way valve located? We have air coming out of our Red glad hand on the A1. TY

Mine was worse - punched a hole in a piston.Where are you sourcing compressors/heads nowadays?

No...... I *bought* one for $160 (free shipping!) off ebay! You have to be watching for those deals.....I am interested in your used compressor, can you send me a link to eBay listing?

My piston seem to have survived.Mine was worse - punched a hole in a piston.

Ebay, surplus channels and surplus truck/parts dealers, Napa, FleetPride, etc. I got a good used compressor for $160 on ebay and rebuilt the head and then rebuilt my original head to carry for a spare.

It's all off-the-shelf Haldex parts.

These guys are an awesome resource also if you don't want to do the work yourself:

Brake Systems Inc. - Manufacturers of Blue Ox Exhaust Brakes

BRAKE SYSTEMS INC. has 40 years of experience Manufacturing, Remanufacturing and Distributing quality brake components. We are ISO 9001:2008 certified. We specialize in Brake and Throttle Components, Electronic Throttle Controls, Exhaust Brakes, Blue Ox Exhaust Brakes, Air Shifters, Air...www.brakesystemsinc.com

Is there a permanent fix for those springs? The parts of the broken spring travelled all the way to the air dryer. I am building an expedition truck and want to make sure it wont happen again.

some of the failures may also be related to the high RPM they must endure at highway speed with the 7.8:1 axle ratio... The only people who run these close to those RPM are the marine users and they don't have air compressors fitted...

You can still see the marks from the cylinder hone in that last pic... After 50K?

drive.google.com

drive.google.com

Have you rebuilt your air drier? If it purges and doesn't close completely that could be the leak.I continue tracking down why the compressor cycles every 2-3 minutes, instead of expected 15m. I have fixed multiple leaks, now if I connect the truck to the shop compressor, put 120 psi in the system, it holds the pressure well. It's hours before the pressure drops to 110 psi. But, if a compressor unload event happens, I start loosing pressure very fast. I disconnected the governor and connected the shop compressor with the pressure gauge to the unload inlet. Looks like it's not holding air at all. Is my new compressor head trash?

See the video:

IMG_1767.MOV

drive.google.com

I bypassed the air dryer, and supplied pressure to the unload port on the compressor. That’s a good theory though, I have checked the exhaust valve at the air dryer and it’s not leaking.Have you rebuilt your air drier? If it purges and doesn't close completely that could be the leak.

We get it, advertisements are annoying!

Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Thanks!