You got it from me it seems. I know the issue you're talking about & mention it in the item description as I have run into it myself on the installations.

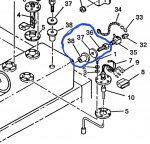

I recently ordered a whole bunch of things from various distributors to try and solve the issue of tanks and the holes not linking up well with the body of the generators. Even with the superior fitting mentioned above, unless you remove the tank, the large brass nut will not seat right & it will never seal right & leak.

I found ONE vendor with a quality fitting that has the same hole size, yet the hex hardware is much smaller.... nearly 50%! This will solve the issue of fitment & alignment with installs & not removing the tank, as well as not needing to make holes in the body bigger.

This will help me stand out for the recent flood of China seller copies of my listings as well.

Also, I wanted to address the issue of the o-ring buldge & overtightening. My goal was to keep the cost down & still have a good, better solution. As well as have a "thick" enough sealing solution to makup for deformed tank walls where the original fitting needed to be yanked out. I have only had a few people complain about it as most people tacking a project like this understand to just tighten it enough not to leak, then slightly more.... like the original fitting. While not the best, once set, it will never leak again. When I started getting the brass bulkhead fittings from the distributor, they did have a bit of a lip to hold the o-ring. I noticed on my last order they don't anymore... that doesn't help.

To address this issue of the o-ring blowing out & still feeling like a tank with deformed walls can be sealed, part of my test order is a bunch of new, viton sealing solutions. One I found that I'm very interested in is one that is stainless & when pressure is applied, is "squeezes" the sealing rubber out to fill all the gaps. So you can CRANK on it as tight as you want! Other solutions coming as well to try.

The "ultimate well nut" solution is still great. The issue has always been stock & shipping. The manufacturer of it drop ships and it ALWAYS cost as much as the nut itself. Most people will get two. So the cost ends up being fairly high, IF you find them. Though, what isn't expensive now.

I've tried multiple times to get the manufacture to respond to me so I, with my business, can bulk order from them. They won't for some reason. If I could buy 1,000 at a time or something and make them a good cost... or at least the same but at least be a reliable, constant source for everyone, I would! But for some reason, they don't seem interested. I'm going to try again though.

Anyways, after all that said, OP, if you haven't already buttoned up, I will send you one of these new, smaller nuts at no cost to be one of the first to try if you want. Supplies may still be a week out to my door. Reply to me directly or via your eBay purchase, or a Direct Message to get it figured out.