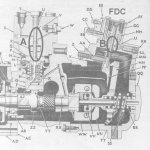

The FDC, actually a device that adjusts the fuel delivery to the engine IP based on its viscosity, not density....

For the fuels specified for this engine in the TMs and on the dash data plate, the "heating value" is directly proportional to the viscosity. That means that if you run on #2 diesel, you need less fuel to produce a given power output compared to gasoline and the "FDC" adjusts the IP stop plate, so that less fuel is in fact made available for a given position of the ""gas" pedal.

The FDC does not work for everything that you may dump in the fuel tank, for example, veggie oil and biodiesel. These fuels have lower heating values than would be indicated by their viscosity, so the FDC reacts in the wrong direction.

The piston and associated parts within the FDC rely on lapped surfaces for metal to metal seals and micron size hard particles can ruin these seals and cause a leak of fuel from the FDC into the IP below and mix with the crankcase oil.

Old steel fuel tanks are not the friend of the FDC (not the IP either for that matter), rust particles too small to be filtered (2 microns or less) can cause a leak.

Guess after 30 or 40 years (truck was designed for 20), you have a choice to replace the fuel tank or bypass the FDC, the metal to metal seals within the IP are still at risk. Perhaps if aluminum fuel tanks had been used, the problem would never had surfaced (no pun intended).