- 1,964

- 435

- 68

- Location

- Culver City, CA

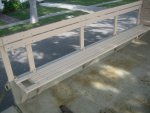

I received my freight shipment of a Duece bed front rack, headache racks and troop seats from Stephan Wood Products truck and trailer parts aftermarket accessories via Roadway (YRC) back on 09-14.

I opted to have them shipped disassembled to save a little on freight charges. Glad I did because I think it eliminated any shipping damage. Everyhting arrived safe and sound with nothing broken, bent or missing.

The head rack slats were packaged in a group of six boards (the two short slats counted as one) wrapped in a heavy-duty cardboard, steel banded and taped.

The troop seats and headache racks slats were packed the same way, but in groups of three slats. So five bundles of slats in all.

There was one pallet (174lbs). It consisted of all the steel uprights (individually boxed), troop seat hinge plates, brackets and cantilever supports, troop seating (stowed) pocking plates and one heavy @$$ bag of hardware (and, yes, every NBW was in there...no more and no less).

Total shipped weight per waybill was 356lbs.

A government spec. drawing of each component was included with hand written instructions on which bolt sizes went where. It made it a lot easier to sort out all the hardware.

I sat on the couch one evening and sorted the hardware by component into heavy zip-loc bags. That made it a lot easier on assembly day(s).

TO BE CONTINUED....

I opted to have them shipped disassembled to save a little on freight charges. Glad I did because I think it eliminated any shipping damage. Everyhting arrived safe and sound with nothing broken, bent or missing.

The head rack slats were packaged in a group of six boards (the two short slats counted as one) wrapped in a heavy-duty cardboard, steel banded and taped.

The troop seats and headache racks slats were packed the same way, but in groups of three slats. So five bundles of slats in all.

There was one pallet (174lbs). It consisted of all the steel uprights (individually boxed), troop seat hinge plates, brackets and cantilever supports, troop seating (stowed) pocking plates and one heavy @$$ bag of hardware (and, yes, every NBW was in there...no more and no less).

Total shipped weight per waybill was 356lbs.

A government spec. drawing of each component was included with hand written instructions on which bolt sizes went where. It made it a lot easier to sort out all the hardware.

I sat on the couch one evening and sorted the hardware by component into heavy zip-loc bags. That made it a lot easier on assembly day(s).

TO BE CONTINUED....

Attachments

-

96.3 KB Views: 28

-

57 KB Views: 27

-

51.7 KB Views: 24

-

51.4 KB Views: 23

-

73 KB Views: 32

-

92.2 KB Views: 25

........... Tim

........... Tim