earnie

Member

- 171

- 0

- 16

- Location

- seattle ,washington,usa

hi Low Tech im not bashing or criticizing you, i am happy that you had the foresight to safty the brake drum hardware but you did it all wrongWe did re-run the safety wires when we did our flipping.

Also drilled and safety wired the bolts on the front of the tranny when we swapped that. Not only were they lose when we pulled it from the parts truck but some were lose in the one we were taking out. Will be pulling that out again and fixing what ever is leaking in the next couple weeks

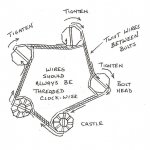

the purpose of safty wiring the hardware is to keep it from backing out, and getting loose ,i am an aircraft mechanic here are some pics one is of what you did and the other show what it is supposed to look like, i hope not to offend you or any one here but it is important to get it right

Attachments

-

76.2 KB Views: 147

-

53.1 KB Views: 167

-

44.7 KB Views: 158