- 10,350

- 94

- 48

- Location

- Meadows of Dan, Virginia

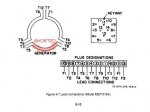

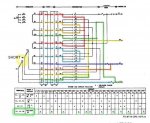

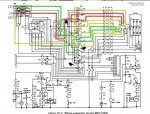

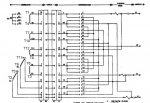

Having made the unpleasant discovery that my 10KW generator suffer from a short circuit between two of its windings, T2, T5 to T8, T11, I wondering how this can happen. Perhaps some of the electrical heavyweights, Isac, Speedemon and others can help explain.

This equipment is extremely well built, IMHO and it looks like fixing this is beyond what I can do here at home.

If there is a parts MEP018 somewhere, let me know.

Does someone have a link to the TM 5-764 manual? I'd like to know how the connections are made to the connector in the back of the unit, can the connector be pulled out for inspection? The diagrams I have don't show how the stator windings are wired to the connector...would be nice if the short was in that part somewhere...

At least, the 4A084 starts easily and runs well now.

TIA

This equipment is extremely well built, IMHO and it looks like fixing this is beyond what I can do here at home.

If there is a parts MEP018 somewhere, let me know.

Does someone have a link to the TM 5-764 manual? I'd like to know how the connections are made to the connector in the back of the unit, can the connector be pulled out for inspection? The diagrams I have don't show how the stator windings are wired to the connector...would be nice if the short was in that part somewhere...

At least, the 4A084 starts easily and runs well now.

TIA

Attachments

-

102.2 KB Views: 23