goldneagle

Well-known member

- 4,737

- 1,508

- 113

- Location

- Slidell, LA

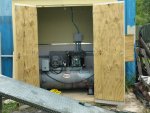

I finally got my WMO filter system put together. I've wanted to do this for a while but procrastinated until now. I have been reading threads on this site for a while learning how other members filtered and used their WMO in their Multifuel engines.

I decided to go with sock filters for most of the filtering process. I also incorporated a large Military fuel water separator into the system. The fuel-water separator is rated 75 gpm.

The Fuel Water Separator uses 1-1/2" quick connect hose fittings. I purchased 1 male and 1 female connector with 1-1/2" Female NPT on other end. I purchased two 1-1/2" to 3/4" NPT reducers. This way I could use 3/4" sch80 PVC pipes fro most of the system.

I ordered 5 of each 100 micron, 25 micron, 5 micron, 1 micron 32" long sock filters. I also purchased four 3/4" SS elbows.

Now I needed a pump to move the WMO through the system. i found a Gas Buggy on Ebay fro $150 plus shipping. It has a 13 GPM air operated dual diaphragm pump on it.

When I got the unit 3 days later I studied how it functioned and found a way to utilize it in my filter system. It has a 34 gallon tank that can be used to store oil. (It's the yellow piece of equipment in the pictures)

I used Unions to make it easier to disconnect certain components in the system for easy storage and moving.

I used a 3/4" pressure treated plywood to hold the filters over the drum for filtering. I routed the edge round to keep it from damaging the filters.

Here is ow the system works:

Using the air operated Gas Buggy with the long pickup tube with the mesh strainer near the bottom inserted into the WMO tank at a pickup location. Insert the discharge hose into the capture container such as a drum or large container. Attach air source to the pump and start pumping the oil. Shut off when capture container is full.

To start the filtering process insert the pickup tube in the WMO container holding the dirty WMO. Insert the 100 micron sock into the 25 micron sock. Insert both socks into the large hole in the plywood lid. The discharge tube goes into the sock. Using an air source pump the dirty oil into the filters until drum is full.

Once the drum is full take the pickup tube a lightly clean it before inserting in to the 2nd drum with the partly filtered WMO (25 micron)

Insert the 5 micron sock filter into the 1 micron filter. Insert the sock filter into the hole in the plywood lid. Place filter over a clean drum. Disconnect the discharge tube at the UNION and reconnect it to the Union attached to the top of the Fuel Water Separator. Make sure the open end goes into the new sock filters. Take the hose with the other half of the Union and connect it to the Union at the bottom of the Fuel Water Separator.

Once the setup is connected, start the pump. The pump will push the 25 micron oil through the fuel water separator and then into the sock filters on the final filtering. When the drum is full turn off pump.

By reconnecting the pump as in phase 1 you can use it to transfer the finished 1 micron oil to a storage tank of the fuel tank of the truck.

See the pictures for details of the system.

I decided to go with sock filters for most of the filtering process. I also incorporated a large Military fuel water separator into the system. The fuel-water separator is rated 75 gpm.

The Fuel Water Separator uses 1-1/2" quick connect hose fittings. I purchased 1 male and 1 female connector with 1-1/2" Female NPT on other end. I purchased two 1-1/2" to 3/4" NPT reducers. This way I could use 3/4" sch80 PVC pipes fro most of the system.

I ordered 5 of each 100 micron, 25 micron, 5 micron, 1 micron 32" long sock filters. I also purchased four 3/4" SS elbows.

Now I needed a pump to move the WMO through the system. i found a Gas Buggy on Ebay fro $150 plus shipping. It has a 13 GPM air operated dual diaphragm pump on it.

When I got the unit 3 days later I studied how it functioned and found a way to utilize it in my filter system. It has a 34 gallon tank that can be used to store oil. (It's the yellow piece of equipment in the pictures)

I used Unions to make it easier to disconnect certain components in the system for easy storage and moving.

I used a 3/4" pressure treated plywood to hold the filters over the drum for filtering. I routed the edge round to keep it from damaging the filters.

Here is ow the system works:

Using the air operated Gas Buggy with the long pickup tube with the mesh strainer near the bottom inserted into the WMO tank at a pickup location. Insert the discharge hose into the capture container such as a drum or large container. Attach air source to the pump and start pumping the oil. Shut off when capture container is full.

To start the filtering process insert the pickup tube in the WMO container holding the dirty WMO. Insert the 100 micron sock into the 25 micron sock. Insert both socks into the large hole in the plywood lid. The discharge tube goes into the sock. Using an air source pump the dirty oil into the filters until drum is full.

Once the drum is full take the pickup tube a lightly clean it before inserting in to the 2nd drum with the partly filtered WMO (25 micron)

Insert the 5 micron sock filter into the 1 micron filter. Insert the sock filter into the hole in the plywood lid. Place filter over a clean drum. Disconnect the discharge tube at the UNION and reconnect it to the Union attached to the top of the Fuel Water Separator. Make sure the open end goes into the new sock filters. Take the hose with the other half of the Union and connect it to the Union at the bottom of the Fuel Water Separator.

Once the setup is connected, start the pump. The pump will push the 25 micron oil through the fuel water separator and then into the sock filters on the final filtering. When the drum is full turn off pump.

By reconnecting the pump as in phase 1 you can use it to transfer the finished 1 micron oil to a storage tank of the fuel tank of the truck.

See the pictures for details of the system.

Attachments

-

75.1 KB Views: 139

-

76.4 KB Views: 176

-

57.7 KB Views: 70

-

57.5 KB Views: 74

-

91.5 KB Views: 76

-

76.3 KB Views: 92

-

84.7 KB Views: 100

-

99.7 KB Views: 113

-

89.8 KB Views: 121