Guys, I think you are making mountains out of ant hills. First off, the load is not uniformly distributed across a uniform span, it is concentrated at the edges of the span, i.e., the bearings. As long as the wheel offset (C/L of wheel) is somewheres between the bearings each bearing will still see a vertical up load, if the wheel is perfectly centered each bearing will THEORETICALLY see an equal load; if the wheel is offset somewhat one bearing will have a slightly higher load than the other.

That is on a straight, level road. What about curves and turns? Now, in addition to the vertical load imposed by the weight of the vehicle, the wheel is applying torque to the bearing set due to the side thrust of the wheel. On a hard right turn, for example, the left inner bearing is seeing a vertical up load at least equal to the total dead weight on the wheel PLUS the dynamic load caused by the torque created by the side thrust forces imposed on the wheel in turning the vehicle; the left outer will see a vertical down force from the turning torque. The bearing loads on the right bearing set will be nearly the same but reversed. Frankly, I doubt the bearings give a damn whether they are loaded up or down, as long as the contact force of each roller to the race remains within design limits the bearings will just keep rolling along.

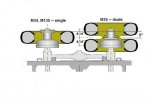

And what about the rear duals? Between mismatched tires, crowned roads and uneven road surfaces the rear bearings are CONSTANTLY being torqued and that torque is CONSTANTLY varying in direction, and assuming the truck is heavily loaded, the total bearing loading is probably in excess of the total front bearing loading.

Remember also that the front and rear AND inner and outer bearings are the SAME bearing, inner bearings have a slightly larger ID but the rollers, races and cages are the same so the bearings are all designed to the same load limits. This is a very different situation, for example, of the front wheel bearings of a rear wheel drive vehicle; here the inner bearing is quite large and the outer bearing much smaller. In this case wheel offset is critical to avoid overloading the smaller outer bearing.

My point? As long as the offset of the wheel places the centerline of the tire somewhere near the center of the bearing, an inch or two one way or the other makes no significant difference!