armytruck63

Active member

- 1,663

- 10

- 38

- Location

- Morro Bay, CA

Nice work!

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Do you have any of the part #s you used? Mouser's site shows that they have about 625,000 military connectors, encompassing 26,000+ pages. I'm not sure how to filter down to the the common styles like you used.I bought the connectors from "Mouser Electronics" . They are a bit spendy but it gives the unit a true military look.

Do you have any of the part #s you used? Mouser's site shows that they have about 625,000 military connectors, encompassing 26,000+ pages. I'm not sure how to filter down to the the common styles like you used.

Is your present truck out of commission ? Anyway thanks for the compliment. As far as the trip goes, we should start some sort of plan. It seems their is a number of people who want to go. I'm still trying to finish my steering project. Parts are still at the machine shop, and I'm unable to work on the truck at present. In a week or so things should calm down here for me to get back at it. We still have a land clearing company here for a few more days, then the house renovation will start. I still need to finish removing all my old trucks and equipment. I have 3 trucks and 4 dozers left. At present I'm only able to work about 5 hours before the pain gets unbearable. So it is taking some time to do all this. Maybe if a set date is established it will light a fire under my butt !Rusty, I love it! It’s design, execution, location, function. Man, you nailed it. It looks great, and, of course, I’m going to assume it works great too.

Well done Rusty, well done indeed!

I have come up with a plan on how to accompany you on the Alaska Trip, but I need another truck from Dallas, or Texas area, (Louisiana, Oklahoma, Arkansas, anywhere “close”, to pull it off.) I’ll post details somewhere appropriate. Maybe I’ll get with you via PM and we can start a thread in the right area to plan this?

Anyway, kudos again on your box, you have done a fantastic job!

No, I have 3 trucks, a couple M923A2’s one is ready to leave in a weeks time, the other one is fine, I just don’t have as many miles behind the wheel to “know” it as well, and a 931A2 that I just got that I wouldn’t take far from home just yet! Still learning this truck, but it seems to be a very nice rig!Is your present truck out of commission ?

Umm, well, that’s between you and your own ass. But, I have found that I usually achieve my goal earlier when I set a date and a goal.Maybe if a set date is established it will light a fire under my butt !

I stand with Greg on this one. I hate crimp connectors as they can allow corrosion to get in or they let you down at the worst moment. I solder every connector and if you want real protection on you wiring get marine wiring as the whole wire is tinned.Looks beautiful. Nicely done.

Personally I never soldier wires on vehicles as the solder makes them more likely to crack, the reason OEM’s do not solder connections. However the use of heat shrink will help support the wires and reduce this.

Thank you very much.I stand with Greg on this one. I hate crimp connectors as they can allow corrosion to get in or they let you down at the worst moment. I solder every connector and if you want real protection on you wiring get marine wiring as the whole wire is tinned.

Nice job on your converter box Greg aka Ruststud.

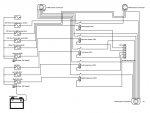

I've been playing with it. I guess it will take awhile to become proficient enough at it to make my diagram. Is there a way to download the program ? Or do you have to buy it to do that ?Per this thread: https://www.steelsoldiers.com/showt...ware-for-drawing-wiring-schematics&highlight=

I was referred to Digikey. Of all the sites recommended, I found it the easiest to grasp.

It took me a few hours, but once I had an idea of how it worked, my schematic went pretty well.

View attachment 729105

You can't download the program, but you can download your diagram. I'm using it as the free version, I don't do a lot of schematics, so I don't wanna' pay if I don't have to. Maybe the paid version allows you to download the software, but I doubt it. It's probably just more capability in the paid version.I've been playing with it. I guess it will take awhile to become proficient enough at it to make my diagram. Is there a way to download the program ? Or do you have to buy it to do that ?

You can't download the program, but you can download your diagram. I'm using it as the free version, I don't do a lot of schematics, so I don't wanna' pay if I don't have to. Maybe the paid version allows you to download the software, but I doubt it. It's probably just more capability in the paid version.

Create a log-in / username on their site, then go here: https://www.digikey.com/schemeit/project/

You can work on your file, save it then go back a week later. I can't remember what I did to create the file, if I printed it or what.

It took me several hours of screwing around with it (I'm not CAD proficient) but once I grasped it, I created it pretty quickly.

I'm going to print the finished schematic out, laminate it and put it inside my box I'm building.

View attachment 729309View attachment 729308View attachment 729310View attachment 729311View attachment 729312