Rattlehead

Member

- 645

- 3

- 18

- Location

- Michigan

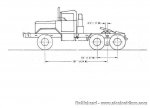

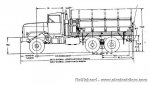

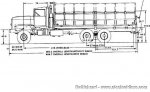

Ok, so I have been thinking of the issues with tire clearance to the landing gear when towing some trailers with military tractors, and decided to figure out some math on the effects of moving the 5th wheel back.

Specifically, I am considering this on a M932 w/w, though the weights and dimensions should be nearly identical for the M818 version. I am running 14's, which causes even more clearance problems than the 11x20 NDT's.

If my math is correct, you can figure out the change in front axle loading by taking the distance of the kingpin from the centerline of the tandem, divide that by the wheelbase (167" in the case of M818's and M931/932), then multiply your result by the expected weight to be applied to your kingpin. If your kingpin placement is in front of the tandem centerline, then the resulting number is ADDED to the front axle weight. If its behind the centerline, SUBTRACT this weight. For a simple example:

----------------------

Frt axle weight unloaded = 10,000 lbs

wheelbase = 167"

stock kingpin placement = 4.5" in front of tandems

So, a 5,000 lb load on your kingpin would result in:

4.5/167 = 0.026946.......

0.026946 x 5,000 = approx 135 lbs, added to front axle loading.

-----------------------

If the kingpin placement was 10" BEHIND the tandems, then the front axle weight would be REDUCED to:

10/167 * 5,000 = 299 lbs REDUCTION.

---------------------

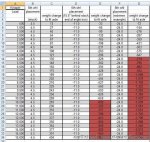

Does this math look correct? If so, the question is, how much weight can you safely pull off the front axle? Attached is a pic from the M939 transport guidance manual that lists axle weights for winch (932) and non-winch (931) tractors, both empty and with the max semitrailer load of 15,000 lbs on the kingpin and 35k lbs total trailer weight. If I can assume that, with a winch-equipped truck, as long as I don't reduce the front axe loading more than the allowed weight of the non-winch truck with full trailer load, I should be ok. You might be able to go more, but that would be the equivalent of simply towing the same load with a non-winch truck. In this case, the EMPTY front axle weight of the winch truck is 10,870 lbs, and the LOADED frt axle weight of the non-winch truck is 10,195, so I could effectively reduce my front axle loading by this difference, 675 lbs, safely.

Remember that this is considering a max capacity trailer, so lighter trailers should provide more of a safety margin.

Also, see the attached spreadsheet, which shows some calculations on various kingpin loads at different placements, IF my math example above is correct? I first show the stock placement. Then 11" behind the tandem centerline, as that is the max distance I can move it back and still attach to the angle iron mounting that is riveted to the side of the frame. I also threw in a 24" just for an extreme, to see the effect. The red shaded portions of this chart are where I would cross the line and bring my front axle loading to BELOW that of a fully loaded non-winch truck.

Does this look correct or am I way off base?

Specifically, I am considering this on a M932 w/w, though the weights and dimensions should be nearly identical for the M818 version. I am running 14's, which causes even more clearance problems than the 11x20 NDT's.

If my math is correct, you can figure out the change in front axle loading by taking the distance of the kingpin from the centerline of the tandem, divide that by the wheelbase (167" in the case of M818's and M931/932), then multiply your result by the expected weight to be applied to your kingpin. If your kingpin placement is in front of the tandem centerline, then the resulting number is ADDED to the front axle weight. If its behind the centerline, SUBTRACT this weight. For a simple example:

----------------------

Frt axle weight unloaded = 10,000 lbs

wheelbase = 167"

stock kingpin placement = 4.5" in front of tandems

So, a 5,000 lb load on your kingpin would result in:

4.5/167 = 0.026946.......

0.026946 x 5,000 = approx 135 lbs, added to front axle loading.

-----------------------

If the kingpin placement was 10" BEHIND the tandems, then the front axle weight would be REDUCED to:

10/167 * 5,000 = 299 lbs REDUCTION.

---------------------

Does this math look correct? If so, the question is, how much weight can you safely pull off the front axle? Attached is a pic from the M939 transport guidance manual that lists axle weights for winch (932) and non-winch (931) tractors, both empty and with the max semitrailer load of 15,000 lbs on the kingpin and 35k lbs total trailer weight. If I can assume that, with a winch-equipped truck, as long as I don't reduce the front axe loading more than the allowed weight of the non-winch truck with full trailer load, I should be ok. You might be able to go more, but that would be the equivalent of simply towing the same load with a non-winch truck. In this case, the EMPTY front axle weight of the winch truck is 10,870 lbs, and the LOADED frt axle weight of the non-winch truck is 10,195, so I could effectively reduce my front axle loading by this difference, 675 lbs, safely.

Remember that this is considering a max capacity trailer, so lighter trailers should provide more of a safety margin.

Also, see the attached spreadsheet, which shows some calculations on various kingpin loads at different placements, IF my math example above is correct? I first show the stock placement. Then 11" behind the tandem centerline, as that is the max distance I can move it back and still attach to the angle iron mounting that is riveted to the side of the frame. I also threw in a 24" just for an extreme, to see the effect. The red shaded portions of this chart are where I would cross the line and bring my front axle loading to BELOW that of a fully loaded non-winch truck.

Does this look correct or am I way off base?

Attachments

-

41.7 KB Views: 784

-

102.1 KB Views: 783