Iron.Horse

Member

- 24

- 25

- 13

- Location

- Frederick, Maryland

Good Evening Guys,

I have a couple questions that have me a little stumped.

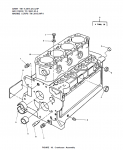

First of all, I have a engine that is pulled from a 400hz unit that is intended to be a donor motor for a 60hz machine with a bad engine. Upon investigation of it, I found that the fuel rack was stuck and I figured that the pumps could use a good cleaning. I have pulled plenty of fuel pumps out before and figured it wouldn't be a big deal. After soaking them for a while, I started reasembly and figured out after a while that slot/pump "3" wasn't cooperating. Every time that pump was introduced into the line-up it caused the rack to have issues. I played with it for quite a while and have ultimately figured out that the internal plunger that pushes up on the fuel pump spring (and thus creates the pumping action/pressure) is in a slightly elevated position not allowing the metering pump to sit down where it is supposed to. I have read that by dead cranking the motor it should change the position of the plunger, but turning the engine over by hand via the front pulley didn't change it's position at all. Is there a reason dead cranking would produce a different result? How else would I get the fuel plunger down? I did spray PB blaster in there to see if it would free up any.

Seccond, I have a unit that I am chasing the elusive "no power" (well actually 30 or so volts, but it isn't field flashing to produce power). I have done VR testing but the readings are all over since there isn't sufficient power to it. I know the OHM testing of the stator (per the TM) is difficult becasue of the tight tolerences and "lower quality" volt meters... At what point do you pull the gen head apart to check the individual components? I believe this was a non-fuse modded unit, so I wouldn't be totally surprised if something is messed up internally.

Also, is there any reason not to use a good engine de-greaser and either wash out or gently power wash the engine bay of a couple fully assembled units that are fairly dirty from leaking fuel lines? I would normally shy away from any water in there but it seems like that is the only way to get rid of the oil residue. I am well aware of not introducing cold water on a hot engine, but my concern is more of the electrical connections...

I have a couple questions that have me a little stumped.

First of all, I have a engine that is pulled from a 400hz unit that is intended to be a donor motor for a 60hz machine with a bad engine. Upon investigation of it, I found that the fuel rack was stuck and I figured that the pumps could use a good cleaning. I have pulled plenty of fuel pumps out before and figured it wouldn't be a big deal. After soaking them for a while, I started reasembly and figured out after a while that slot/pump "3" wasn't cooperating. Every time that pump was introduced into the line-up it caused the rack to have issues. I played with it for quite a while and have ultimately figured out that the internal plunger that pushes up on the fuel pump spring (and thus creates the pumping action/pressure) is in a slightly elevated position not allowing the metering pump to sit down where it is supposed to. I have read that by dead cranking the motor it should change the position of the plunger, but turning the engine over by hand via the front pulley didn't change it's position at all. Is there a reason dead cranking would produce a different result? How else would I get the fuel plunger down? I did spray PB blaster in there to see if it would free up any.

Seccond, I have a unit that I am chasing the elusive "no power" (well actually 30 or so volts, but it isn't field flashing to produce power). I have done VR testing but the readings are all over since there isn't sufficient power to it. I know the OHM testing of the stator (per the TM) is difficult becasue of the tight tolerences and "lower quality" volt meters... At what point do you pull the gen head apart to check the individual components? I believe this was a non-fuse modded unit, so I wouldn't be totally surprised if something is messed up internally.

Also, is there any reason not to use a good engine de-greaser and either wash out or gently power wash the engine bay of a couple fully assembled units that are fairly dirty from leaking fuel lines? I would normally shy away from any water in there but it seems like that is the only way to get rid of the oil residue. I am well aware of not introducing cold water on a hot engine, but my concern is more of the electrical connections...